1 / 5

2 / 5

3 / 5

1 / 4

1 / 5

1 / 5

1 / 5

Dr. Suhas Joshi is currently the Director, IIT Indore. He is a Fellow of the Indian National Academy of Engineering, and the National Academy of Sciences.

Prior to joining IIT Indore as the Director, Dr. Joshi served as a Rahul Bajaj Chair Professor in the Department of Mechanical Engineering at IIT Bombay. He also served as the Dean of Alumni and Corporate Relations (2017-2022) and the Head of Mechanical Engineering Department (2014-1207) at IIT Bombay. He served as a Visiting Faculty in Mechanical Science and Engineering at the University of Illinois at Urbana-Champaign, USA (2005-06).

Dr. Joshi has been a recipient of BOYSCAST fellowship of Govt. of India (2002), ‘Best Faculty’ award of Mech. Eng. Dept., IIT Bombay (2007), and ‘Dr. P. K. Patwardhan Technology Development Award’ of IIT Bombay (2008).

Dr. Joshi works on improving the productivity and quality of multi-scale machining processes through physics-based modeling and characterization. He has undertaken over 38 research, consultancy, and infrastructure development projects sponsored by aerospace, nuclear, defense, and private organizations in India. He has established excellent research infrastructure for micromachining, laser micro-machining, and titanium machining. During 2009-14, he spearheaded the establishment of ‘National Centre for Aerospace Innovation and Research (NCAIR)’, at IIT Bombay as its founding Principal Investigator. The centre is an industrial consortia mainly sponsored by Govt. of India, The Boeing Company, and IIT Bombay.

Dr. Joshi has served as an Associate Editor of Trans. ASME, Journal of Manuf. Sci. and Eng. (2007-14). He is presently an Associate Technical Editor of Machining Sci. and Technol. (Taylor and Francis) (2010-) and, the Editorial Board Member of International Journal of Machine Tools and Manuf. (Elsevier) (2013-2018) and Indian Journal of Engineering & Materials Sciences, CSIR-NISCAIR (India) (2015-).

Dr. Joshi has supervised a post-doctoral and 18 doctoral students. He is presently guiding another 6 doctoral students for their Ph.D. He also has supervised more than 112 masters dissertations at IIT Bombay. Dr. Joshi has over 300 publications including 179 in referred international journals and five book chapters to his credit. He has a phenomenal h-index of 41 (Google Scholar).

Department of Mechanical engineering

IIT Bombay, Mumbai, India

Department of Mechanical engineering

IIT Bombay, Mumbai, India

Department of Mechanical Science and Engineering

University of Illinois, Urbana-Champaign, IL, USA

G.W. Woodruff School of Mechanical Engineering

Georgia Institute of Technology, Atlanta, GA, USA

Department of Mechanical engineering

IIT Bombay, Mumbai, India

IIT Bombay, Mumbai, India

IIT Bombay, Mumbai, India

National Centre for Aerospace Innovation and Research (NCAIR)

IIT Bombay, Mumbai, India

Engineering Research Center, Tata Motors (India) Ltd., Pune, India

IIT Bombay, Mumbai, India

National Institute of Technology, Tiruchirapalli, India

V. J. T. I., Bombay,India

| S.No | Product or Process developed | Purpose | Novelty | Implimentation or validation |

|---|---|---|---|---|

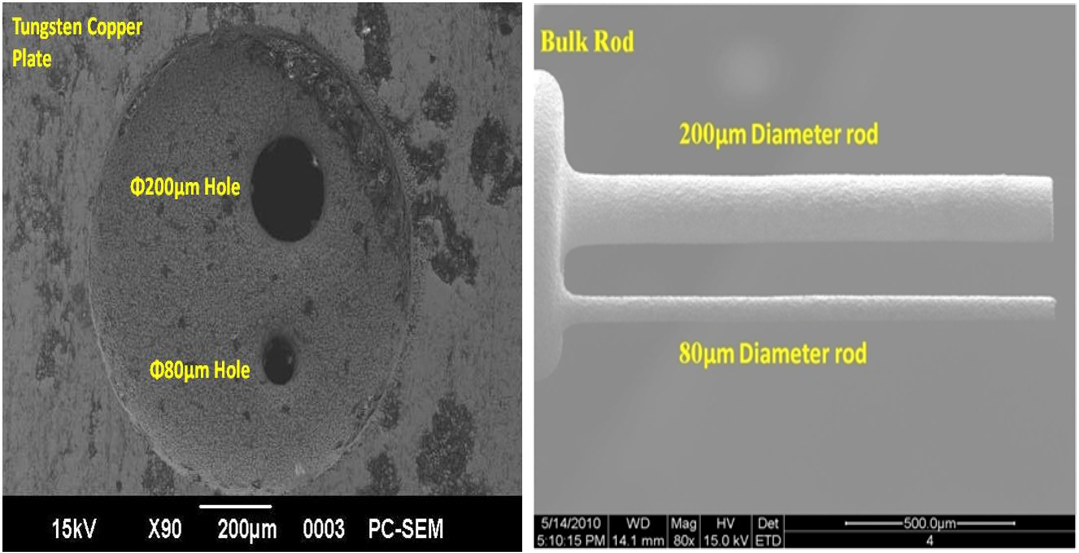

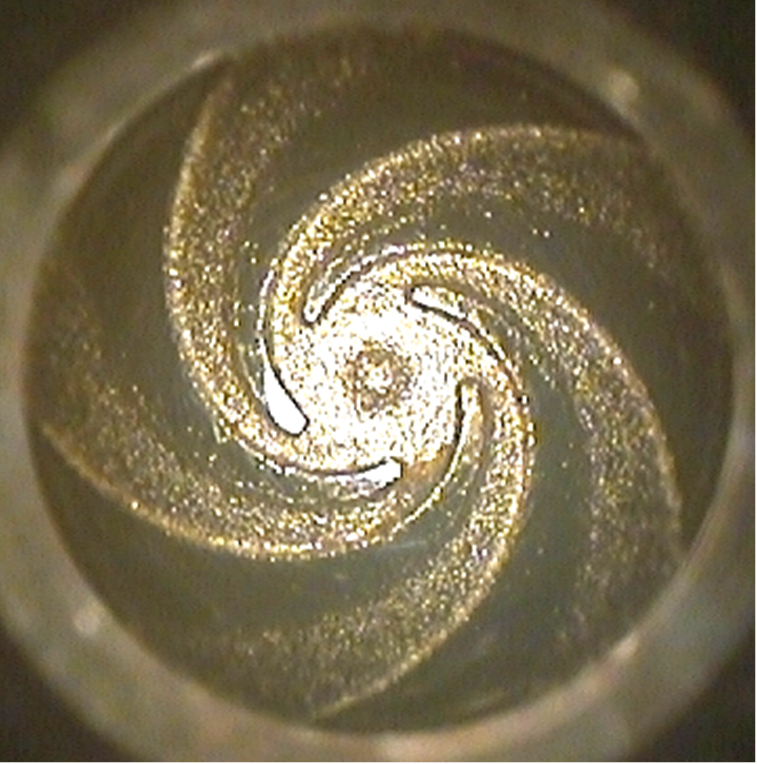

| 1 | Spherical punches of ∅6 mm with spiral micro-grooves 60-100 µm deep using micro-EDM12,19,24.

|

Spiral grooves with varying depth provide squeezing action on the hydrodynamic fluid being circulated around the punches. They help maintain a positive hydrodynamic film reducing the friction substantially | Manufacturing the grooves with micro-EDM after hard turning of the spherical punches. Both were new processes that were developed. | 25 Nos. of punches where fabricated in the lab and were supplied to BARC for strategic applications. Each punch requires 8-10 hrs. of manufacturing. |

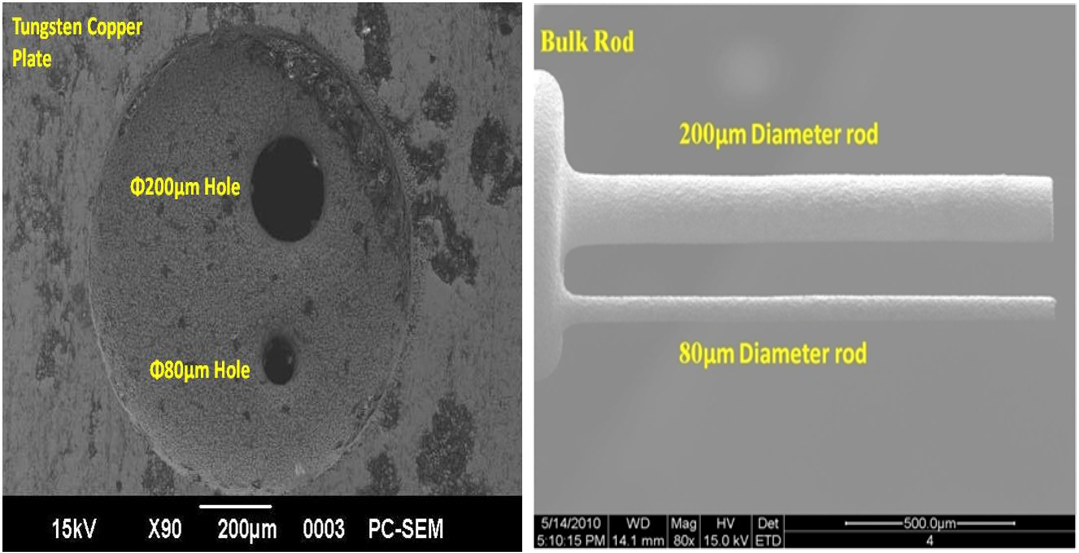

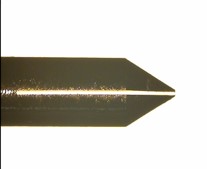

| 2 | Nano-deliver pins: 40 µm wide 4.5 mm long slit using micro-wire-EDM17,32.

|

The pin carries captured liquid by capillary action and releases nano-liters volume on a surface when touched. Usually, an array of 20 pins is used to transfer fluid dots, each of nano-liters volume. | Manufacturing was attempted by various methods but micro-wire-EDM gave very consistent results. | 20 Nos. of nano-delivery pins were fabricated in the lab and were supplied to BARC for strategic applications. Each pin requires 4-5 hrs. |

| 3 | Micro-pin-hole matrix with 70 holes : ∅60 µm & spehericity tol. <3 µm on a thin foil of 100 µm.

|

It is used as for light diffraction in optics field.

|

Micro-EDM is the best for drilling on thin foils. A W electrode ∅60 µm was hard micro-turned and was used as electrode for in-situ EDM drilling of the foil. | 2 Nos. of micro-pin-hole matrix were fabricated in the lab and were delivered to RRCAT for strategic applications. Each matrix requires 8-10 hrs. |

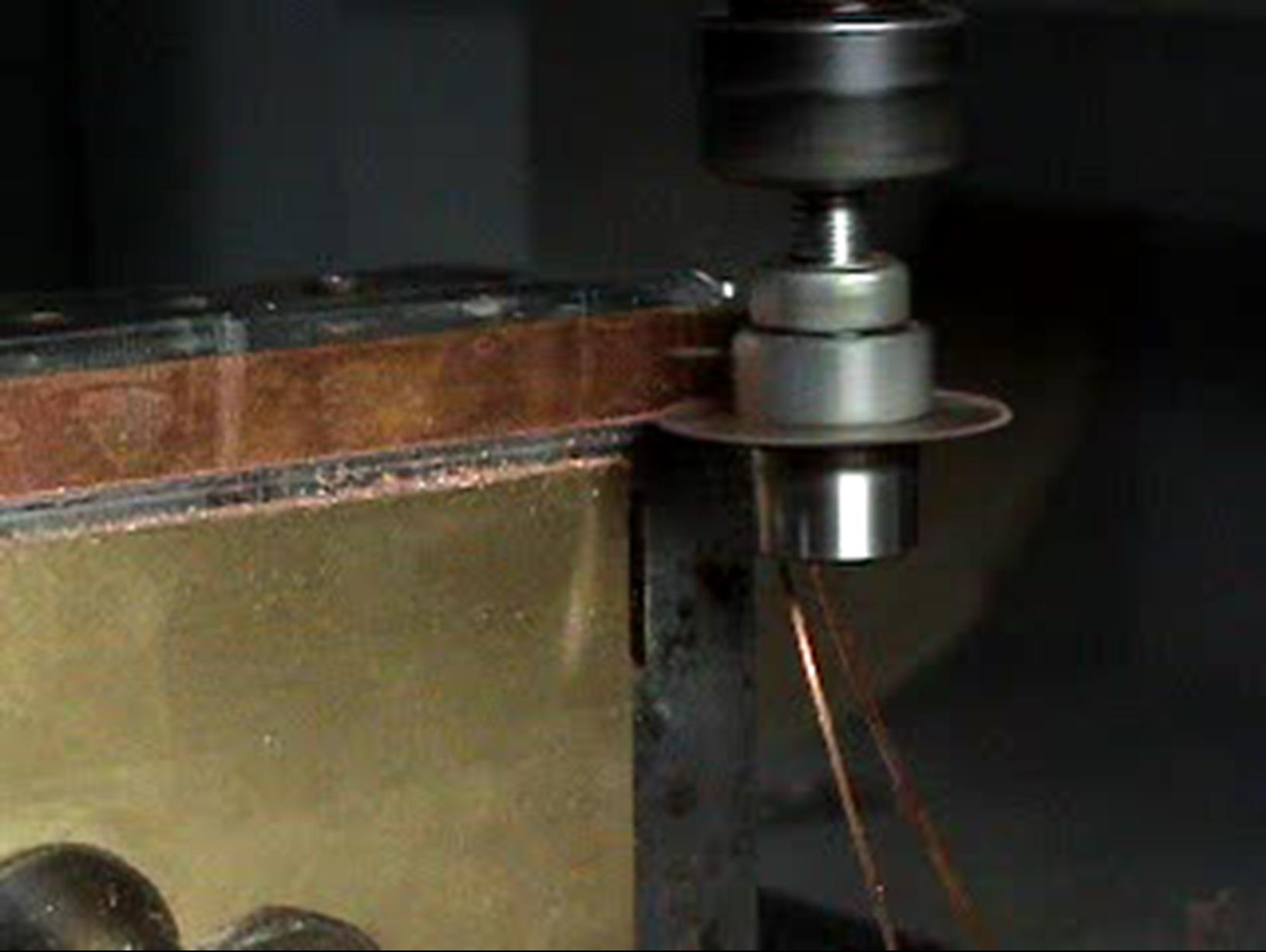

| 4 | Micro-channels for micro-heat exchangers of 60 µm depth on a copper foil of 100 µm thick. 400 µm wide and 100 mm long.

|

To fabricate a micro-heat exchanger such foils are needed.

|

A new process of peripheral micro-milling was developed to make a 400 µm wide peripheral milling cutter. The process can generate the micro-channels over longer lengths. | Over 100 pieces of components with 4 parallel micro-channels each of length 100 mm were fabricated in the lab and were delivered to BARC for strategic applications. Time for each foil is ~1/2 hr. |

| 5 |

Laser LIGA for polymer micro-fabrication: It involves 3 stages: fabrication of soft mold by laser lithography, hard mold by electro-deposition and arrayed features by hot embossing. |

The process can be used for replication of arrayed features on polymers

|

Laser LIGA is a new three stage process and has been established successfully in the laboratory. | The process knowledge and its experimental details were made available to BARC for strategic applications. |

| 6 |

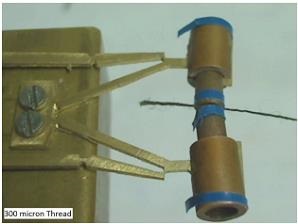

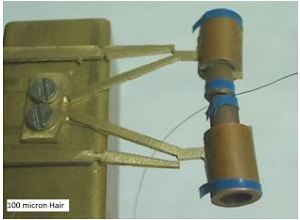

Laser LIGA for pForce sensing micro-gripper38,101: It uses a micro-gripper with flexural joints having two jaws with concentric cylinders housing a spring.

|

It is used to maneuver micro-components that are delicate. The force required for holding a thread is 62 mN and for hair is 43 mN.

|

Concentric jaws containing springs coupled with a vision system for tracking displacement of jaws. The vision system works on a specific algorithm. | One assembly of the entire system was developed and is coupled also with a linear actuator has been developed for BARC. |

| 7 |

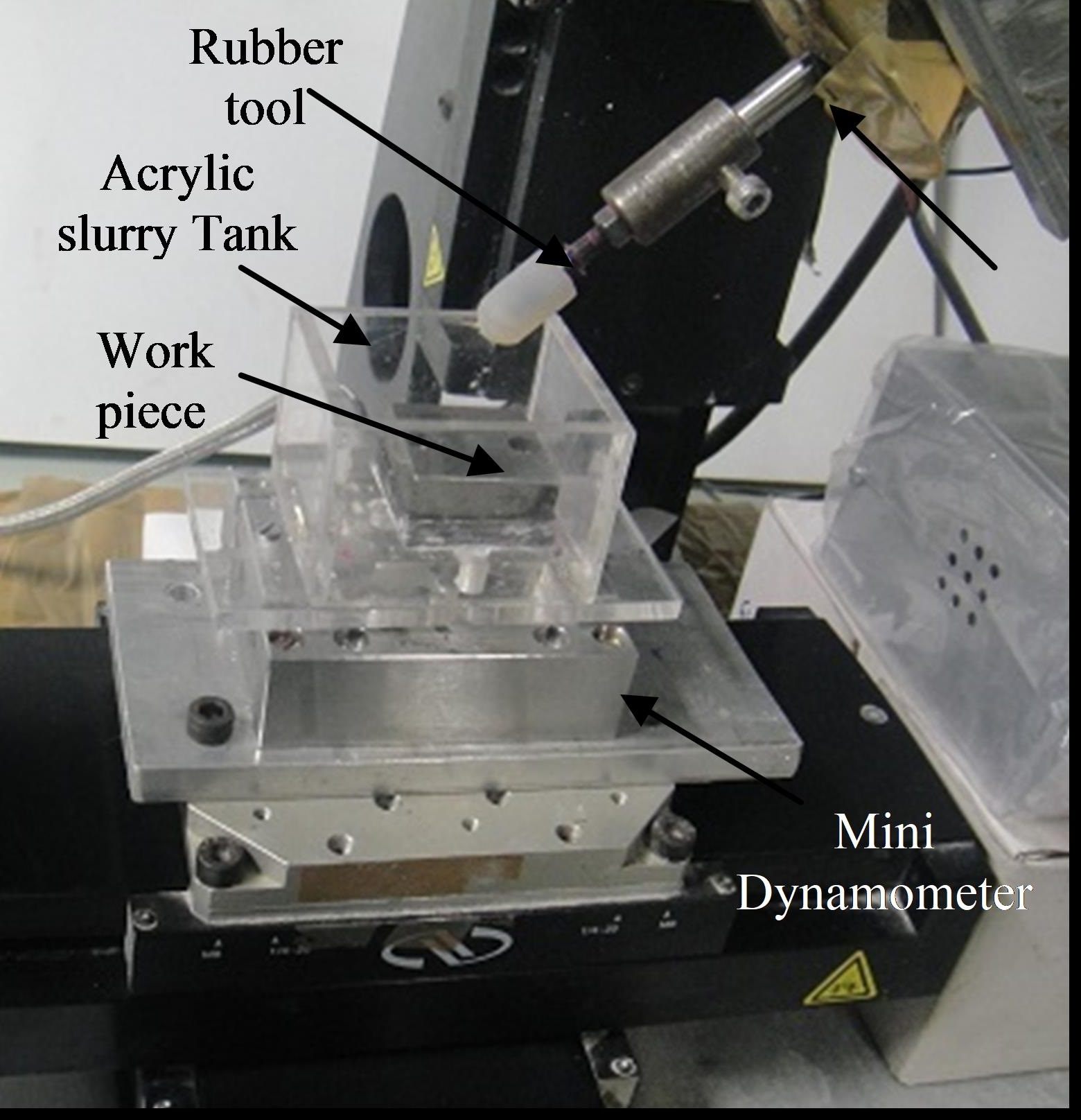

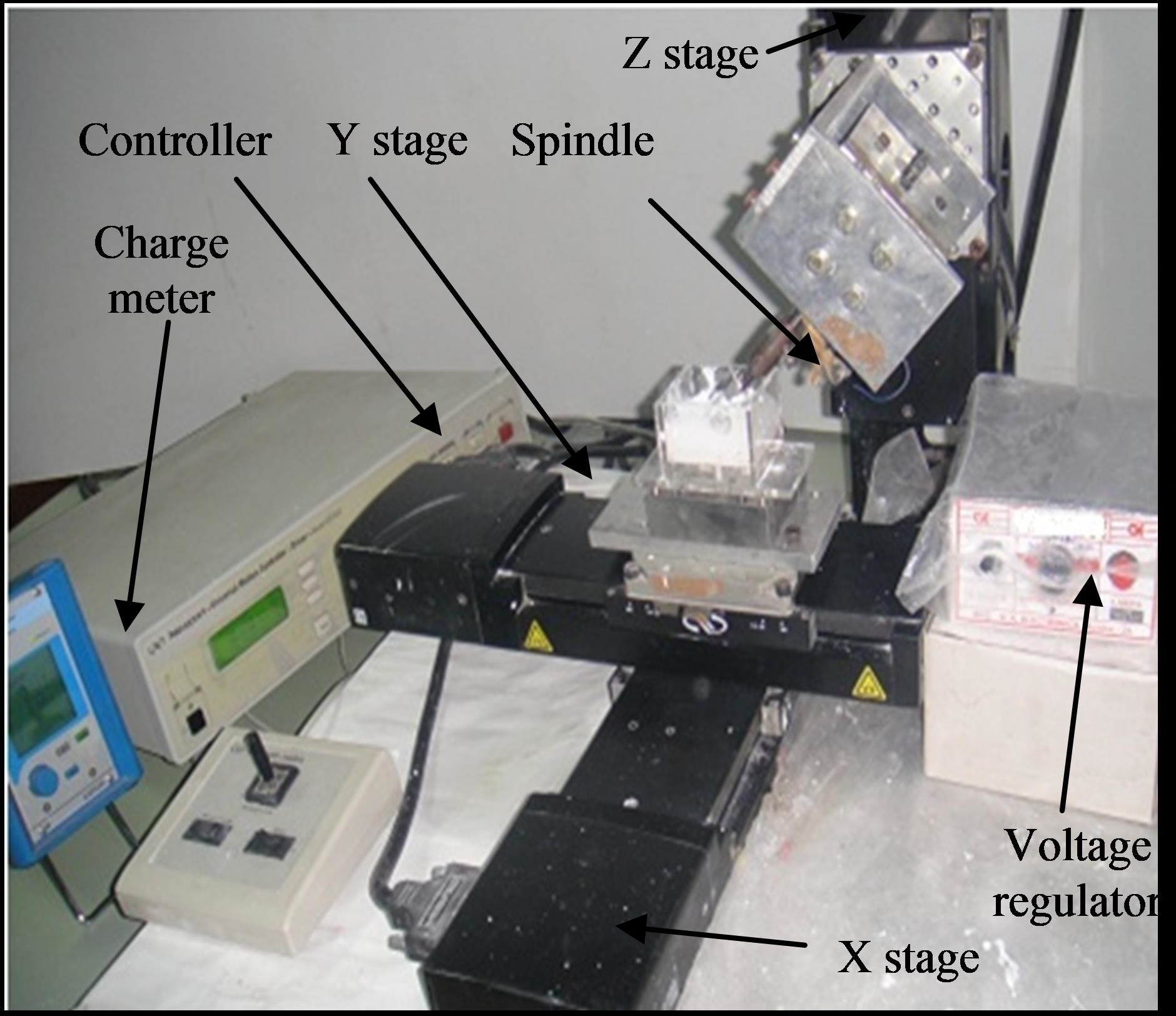

Hydrodynamic nano-polishing of hard crystals54,61: It uses a hydrodynamic film formed between a soft, low modulus rotating tool and workpiece submerged in a suspension of abrasives in viscous slurry.

|

The machine performs hydrodynamic polishing of flat and conformal single crystal sapphire for bearings application. Surface finish ~100 nm Rs has been achieved on the sapphire crystals.

|

Establishment of processing conditions for nano-polishing of hard crystals such that hydrodynamic film is maintained between the polisher and the crystal surface. | One machine including x-y-z-axes slides and nano-polishing attachment has been delivered to BARC for nano-polishing applications. |

| 8 |

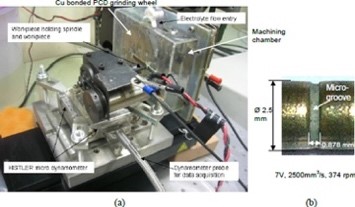

Micro-Electrochemical-Grinding23,68: It involves use of metallic bonded PCD grinding wheel of 300-800 µm thickness to perform electrochemical grinding process. Whole process of micro-ECG is done in a closed chamber so that contamination is avoided. |

It is used to generate slots of 800 µm thickness on workpieces made of brass.

|

A dedicated machine for micro-ECG is developed with x-y-z axes controllers. | One machine including x-y-z axes slides has been developed along with a specifically designed grinding as well as work holding spindles was developed for BARC applications. |

| 9 |

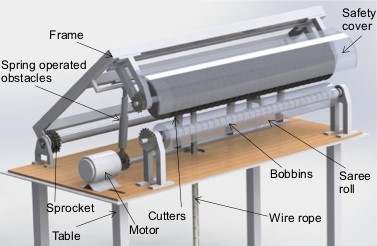

Saree ribbon cutting machine for handlooms operated by visually-challenged individuals. The machine uses 27 cylindrical disc cutters to cut ribbons from old sarees of 2” width. |

This machine was developed to avoid drudgery in making ribbons for weaving 6’x6’ mats. Earlier manual cutting the ribbons was the most time-consuming activity.

|

The machine prepares 27 bobbins wrapped with ribbons in-situ in a single downward action of the cutters. These are sufficient to weave one mat. | The machine was implemented at NGO at Latur (Maharashtra). |

| 10 |

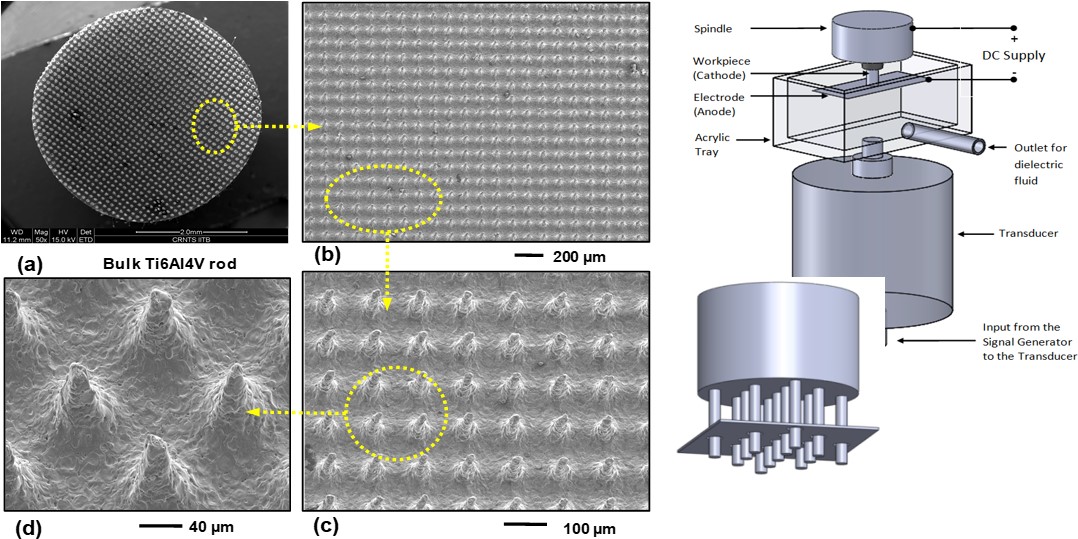

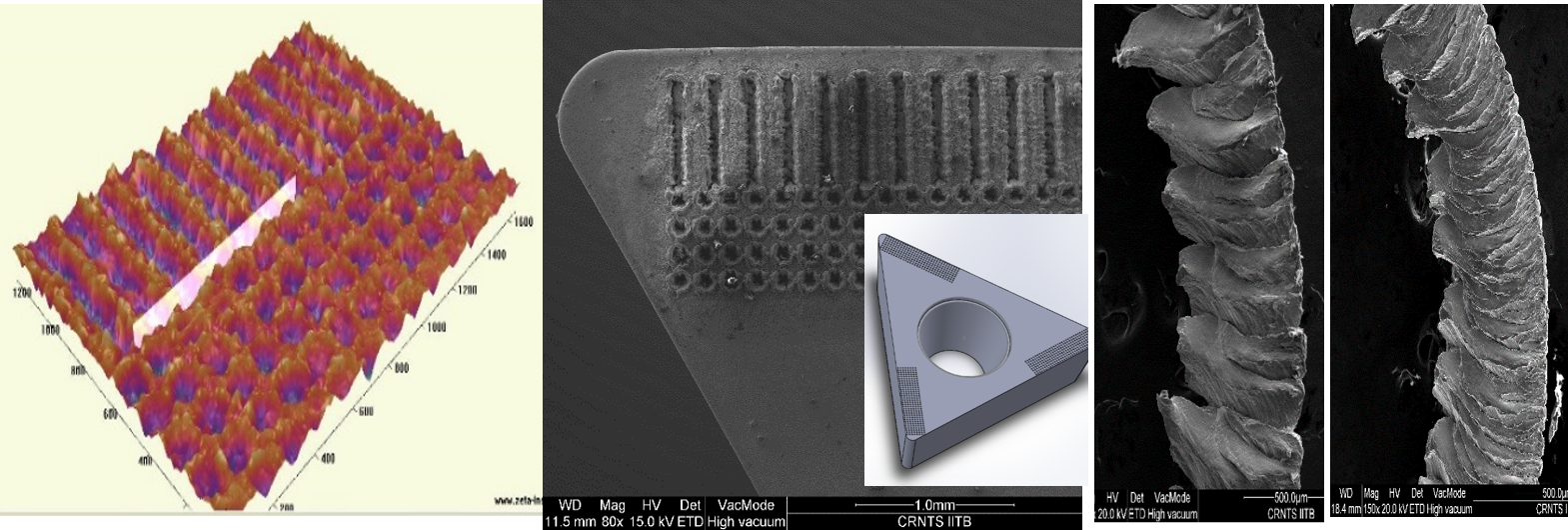

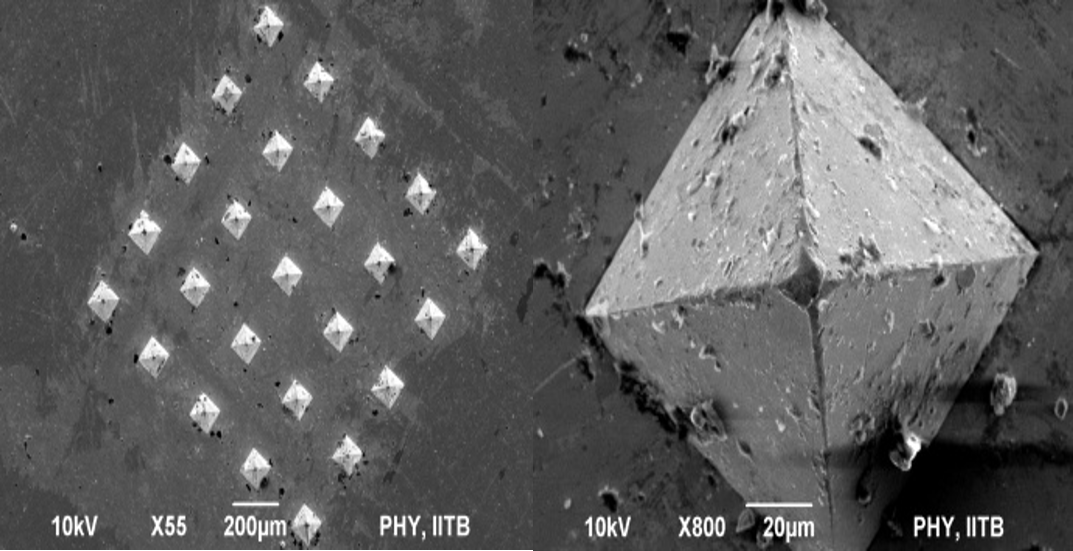

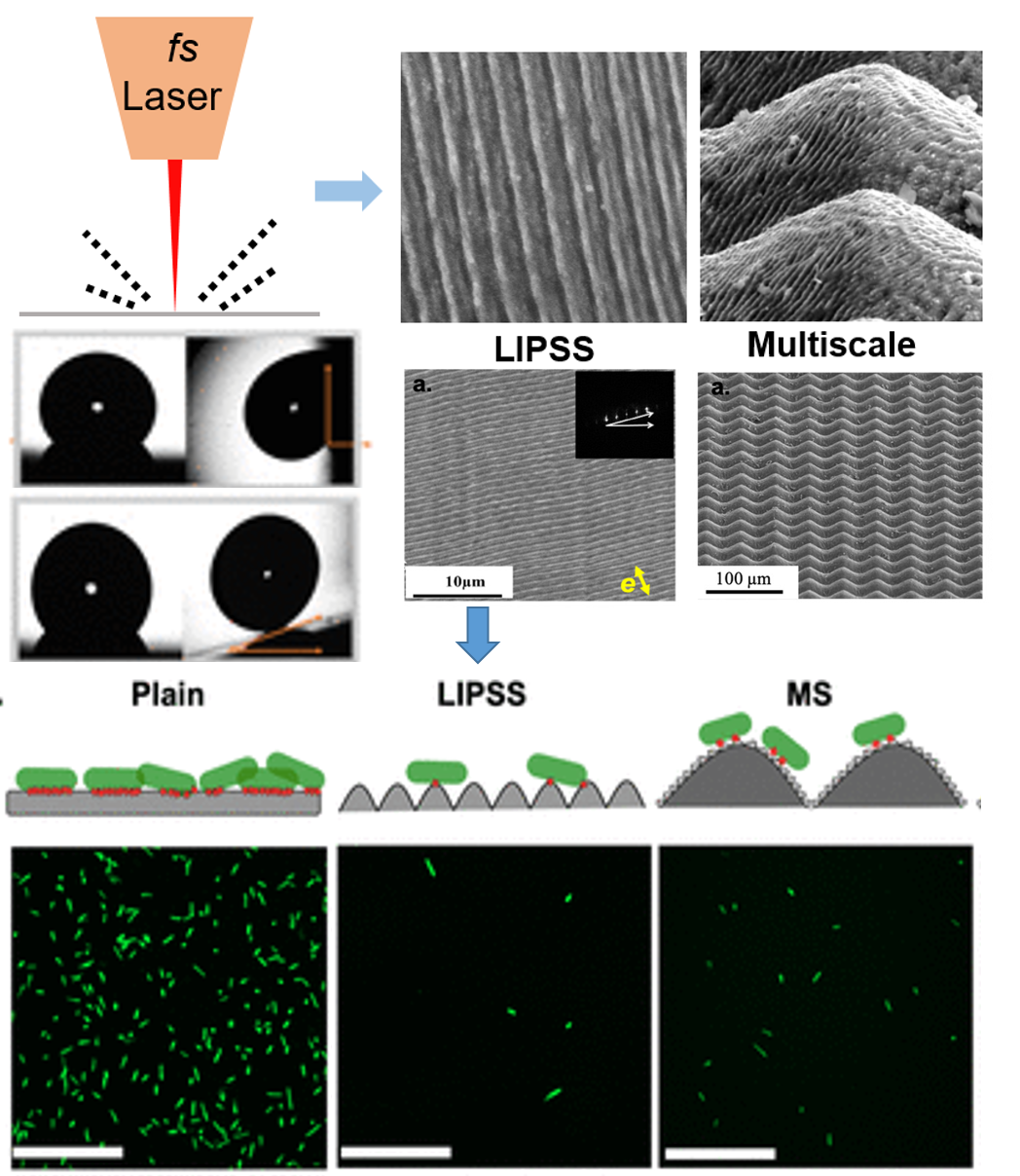

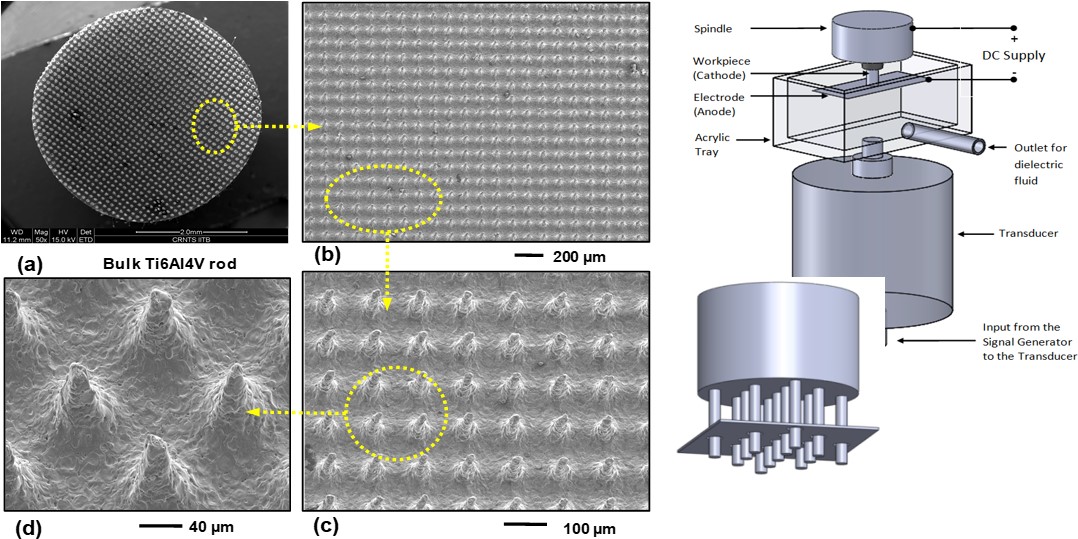

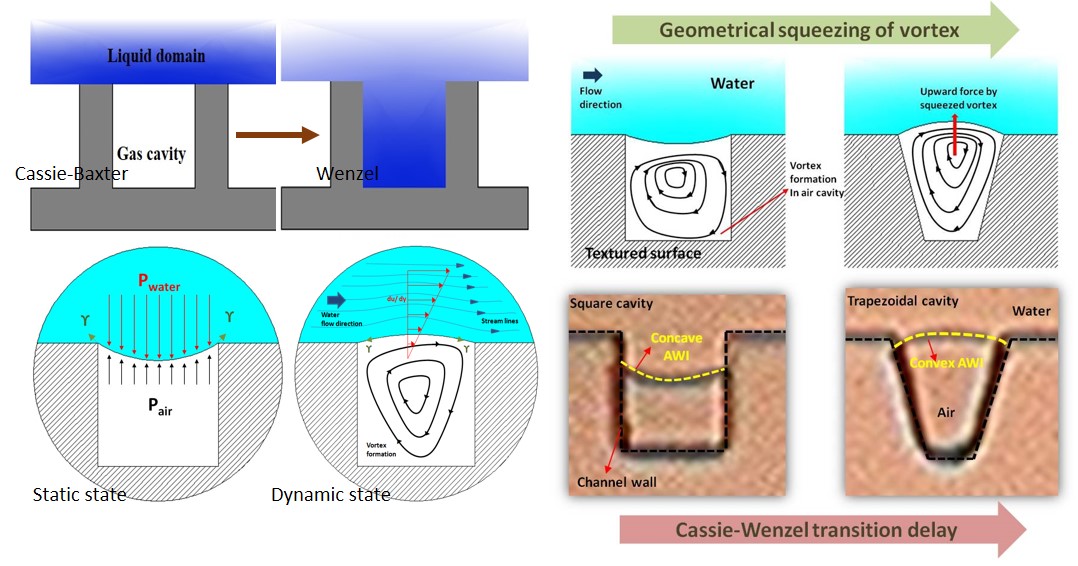

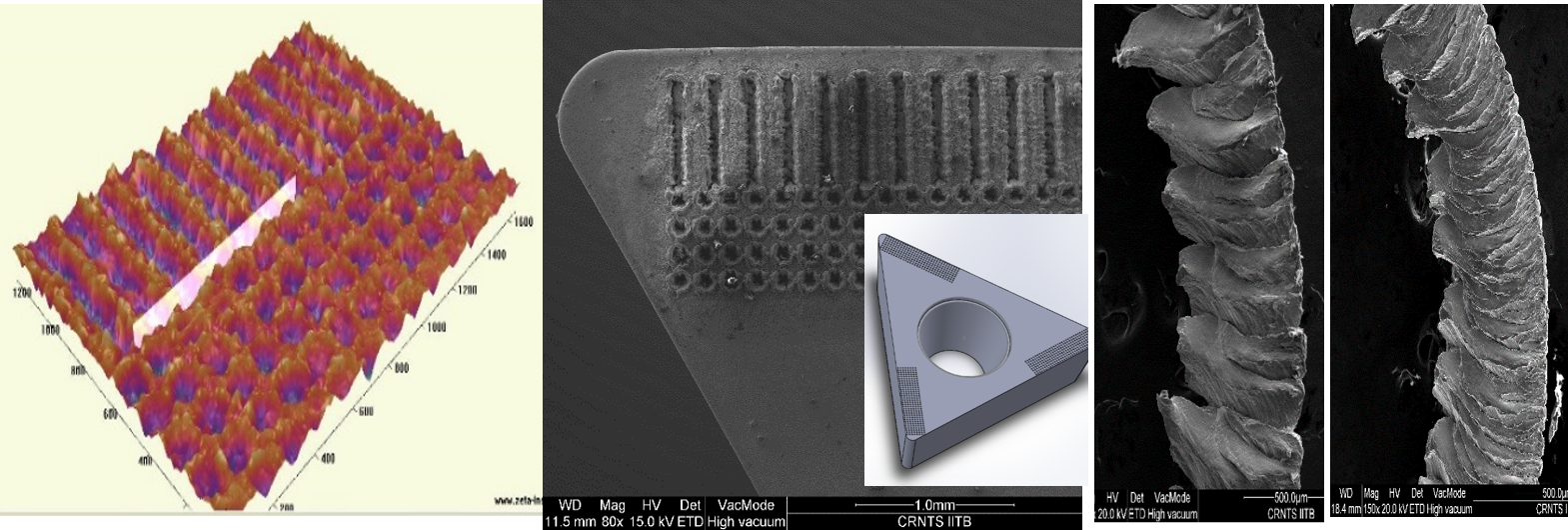

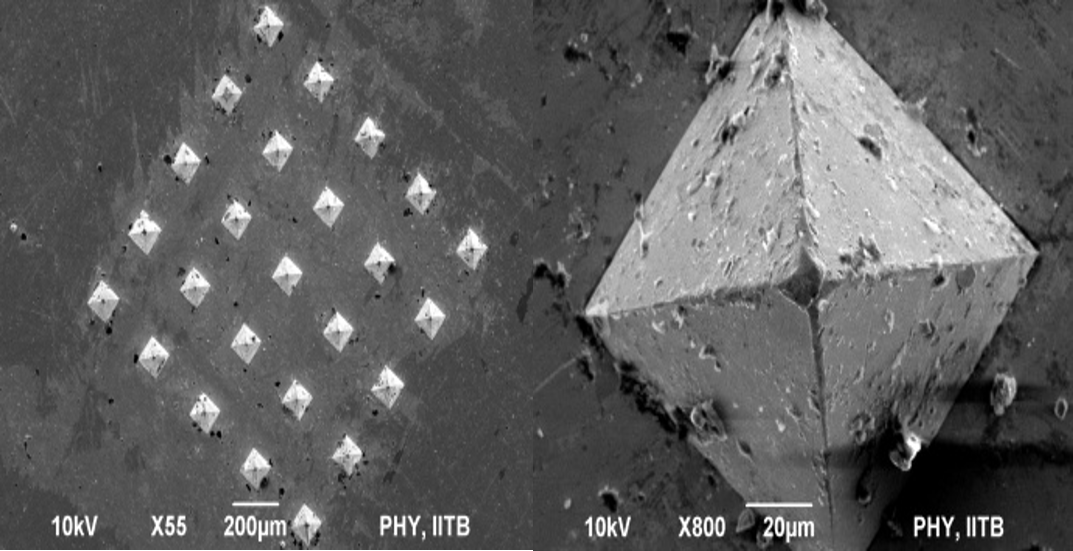

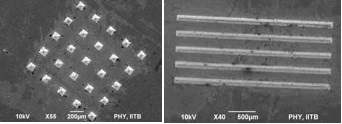

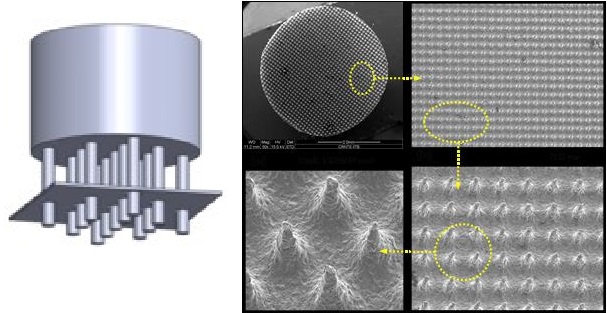

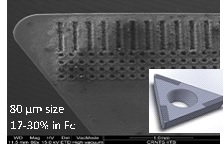

Textured surfaces using reverse-micro-EDM33,51,55,75 and Laser micro-machining: In this process, a low-aspect ratio structure is formed on work surfaces by sinking a perforated electrode.The textures were also fabricated by direct writing by lasers.

|

These structures reduce drag to the fluid flowing over them. The textures formed on the cutting tools reduce cutting forces by 17-30%.

|

It is new process and was developed for texturing of surfaces for the first time. Two different types of textures were prepared on the tools faces for sticking zone and sliding zones. | The process was developed as part of project sponsored by DST, GoI and ISRO |

| 11 |

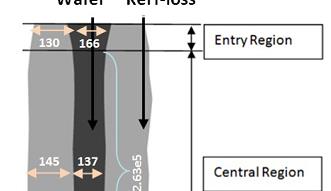

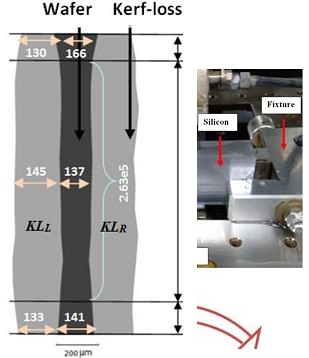

Ultra-thin Si wafer slicing by wire-EDM52,65,66,86. Use of wire-EDM to slice Si wafer enables thickness of 150 µm in place of 300-400 µm by mechanical diamond saws.

|

These wafers are necessary for photovoltaic applications.

|

The application of wire-EDM in ultra-thing Si wafers slicing was demonstrated for the first time. | This process was developed as a part of sponsored project by MNRE, GoI and Applied Materials Company. |

| 12 |

Ultrasonic vibration assisted tapping of Ti alloys103,84: Often taps get jammed in Ti alloys due their low elastic modulus, especially when they are M3-M4 size. This attachment gives axial and torsional vibrations to reduce the friction and clogging of chips. Simulation of fundamental cutting showed 17% and 33% reduction in Fc and Ft. |

Used for tapping of small holes on Ti alloy.

|

Imparting combined axial and torsional vibrations in tapping of small holes is the novelty here. | This process was developed as part of two M.Tech. dissertations sponsored by M/s Bharat Forge, Pune |

|

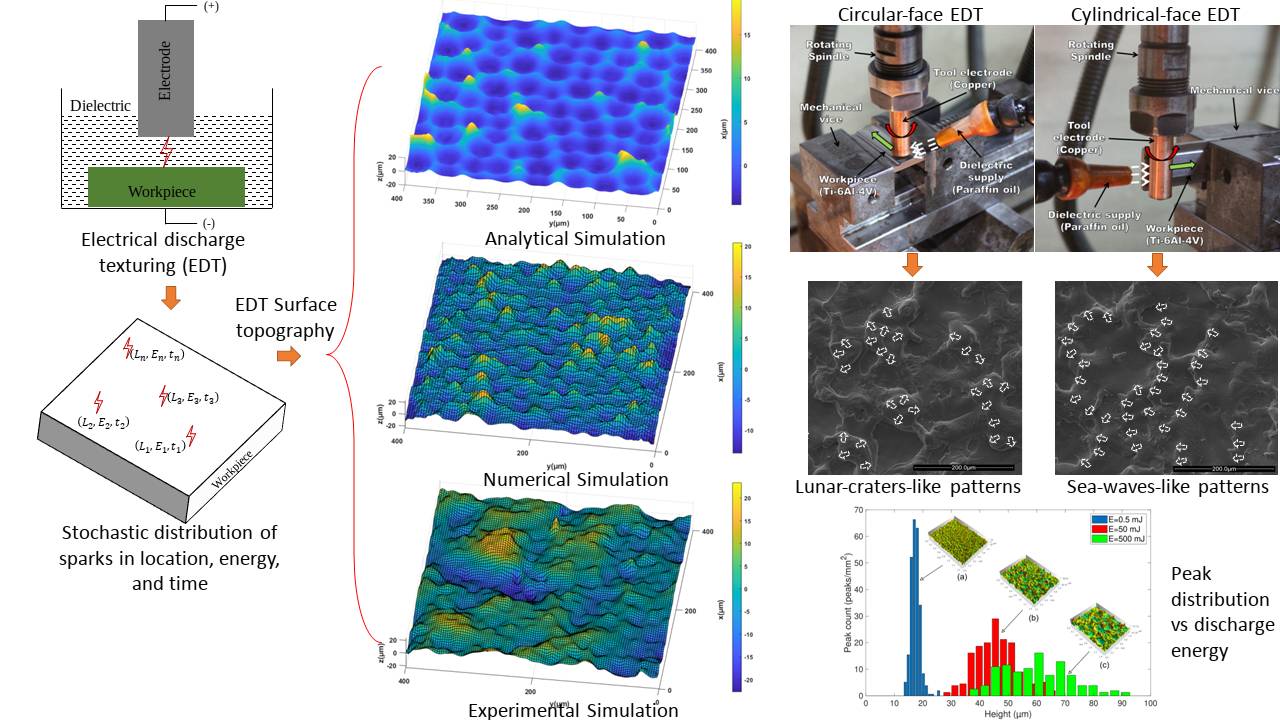

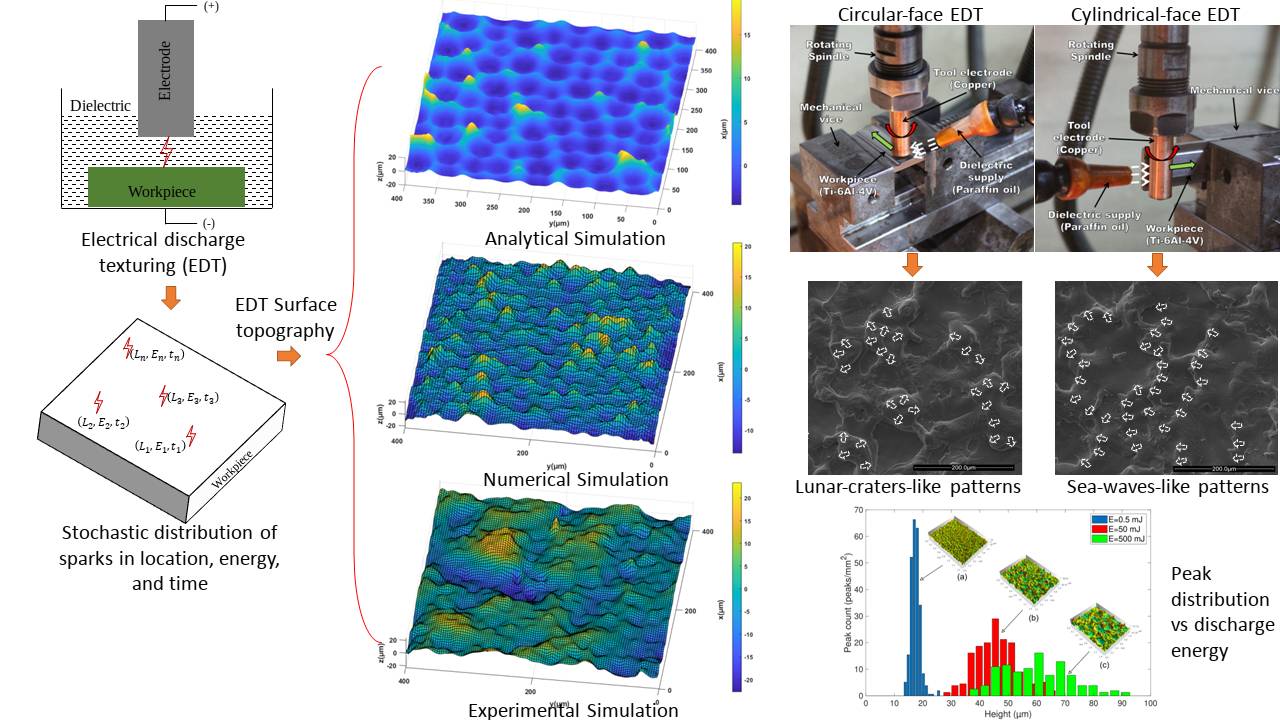

Jithin’s research topic is 'Modelling and Analysis of Surface Topographies Generated using Electrical Discharge Texturing (EDT)'. His work focuses on the investigation and evolution of the EDM process towards the generation of rough textured surfaces and characterizing the textures generated with respect to different functional properties they exhibit. It also focuses on the development of analytical and numerical models for prediction of surface texture generated through EDM process under different operating conditions. His research interest is in Surface texturing, EDM, Micromachining, Surface properties. He received his M. Tech in Mechanical Engineering from NIT Calicut in 2013. He did his B. Tech in Mechanical Engineering from College of Engineering, Trivandrum in 2009. jithins.iitb@gmail.com |

|

Ashwani’s research topic is ‘Investigating micro and nanoscale material removal mechanism in ductile and brittle materials’. Different materials show various kind of machining characteristics when deformed at micro to nano-scale. Minimizing the ploughing phenomena in case of machining ductile materials and suppressing the crack formation in case of machining brittle materials is the primary goal of research in order to achieve the shearing dominant cutting and smooth surface. His research interests are cutting tool design, on machine tool fabrication, MQL system analysis and analytical analysis of material removal at micro-scale. Ashwani completed his Ph.D from IIT Patna and did his M.Tech from NIT Warangal. '. ashwanipratap2012@gmail.com |

|

Yogesh’s Ph.D. topic is 'Modeling of machining of multi-layered composites'. using experimental and numerical techniques. The motivation of work is to study the effect of conventional drilling, peck drilling and helical milling quality of hole produced in multilayer metal-composite. His research interest is in Difficult to machine materials, Machining of composites, and Finite element modeling of manufacturing processes. He received his M. Tech in Mechanical Engineering from Dr. Babasheb Ambedkar Technological University, Raigad in 2013. He did his B.E in Production Engineering from K. K. Wagh Institute of Engineering Education & Research in 2011. yogeshgaikhe@gmail.com |

|

Ankit’s Ph.D. topic is 'Thermal Modeling of Drilling Titanium under Various Cooling Strategies'. His research work is to develop a comprehensive heat transfer model for drilling process and its effective modes of heat dissipation techniques. The main aim is to determine the heat generation and temperature distribution in drilling process by considering all three zones of deformation. He is jointly guided by Prof. Rajneesh Bhardwaj. His area of interest is heat transfer, fluid dynamic, computational fluid dynamic and Finite element modeling. He did his B.Tech in Mechanical Engineering from GLAITM, Mathura in 2012. He worked as an Engineer from 2012-13 at Enco Engineers Combine Pvt. LTD, Gurgaon. ankitkumar26jan@gmail.com |

|

Vishwas’s Ph. D topic is 'Drilling-induced damages and their effects on strength and fatigue life of CFRP composites'. Due to poor machinability, drilling of CFRP is always associated with damages such as pre pull-out or breakage, matrix cracking or thermal degradation, delamination, etc. Therefore, it is essential to understand the effects of these damages on strength and life of CFRP components. His research interest is in Finite element modeling of manufacturing processes, machining of composites. He completed his B. tech in Production engineering (SGGS Institute of engineering and technology, 2012) and M. Tech from Production engineering (IIT Delhi, 2014). Two years of teaching experience in mechanical department of RGUKT Basar (2012-14). divse.vish@gmail.com |

|

Mr. Srinivasa Rao Nandam is pursuing PhD under external category through sponsorship by DRDO. Mr. Srinivas’s PhD topic is "Surface Damage Aided Machining of Advanced Cast Nickel Based Superalloy." Single-crystal Nickel based superalloys have superior gas turbine engine performance and durability. But, single-crystal nickel based superalloys are considered as difficult-to-cut materials. The research work involves weakening the surface layer through developing certain surface defects by using a high power continuous wave fiber laser. This damaged surface layer will be removed by bulk machining operation thereafter. His research interests are advanced manufacturing techniques and precision engineering. He has completed his M.Tech from IIT Madras and B.Tech from College of Engineering, JNTU, Hyderabad. He has over 20 years of industrial experience. Presently, Mr. Srinivas is working as Scientist – ‘F’ and Head, Mechanical Engineering Group of DMRL, DRDO, Hyderabad. |

|

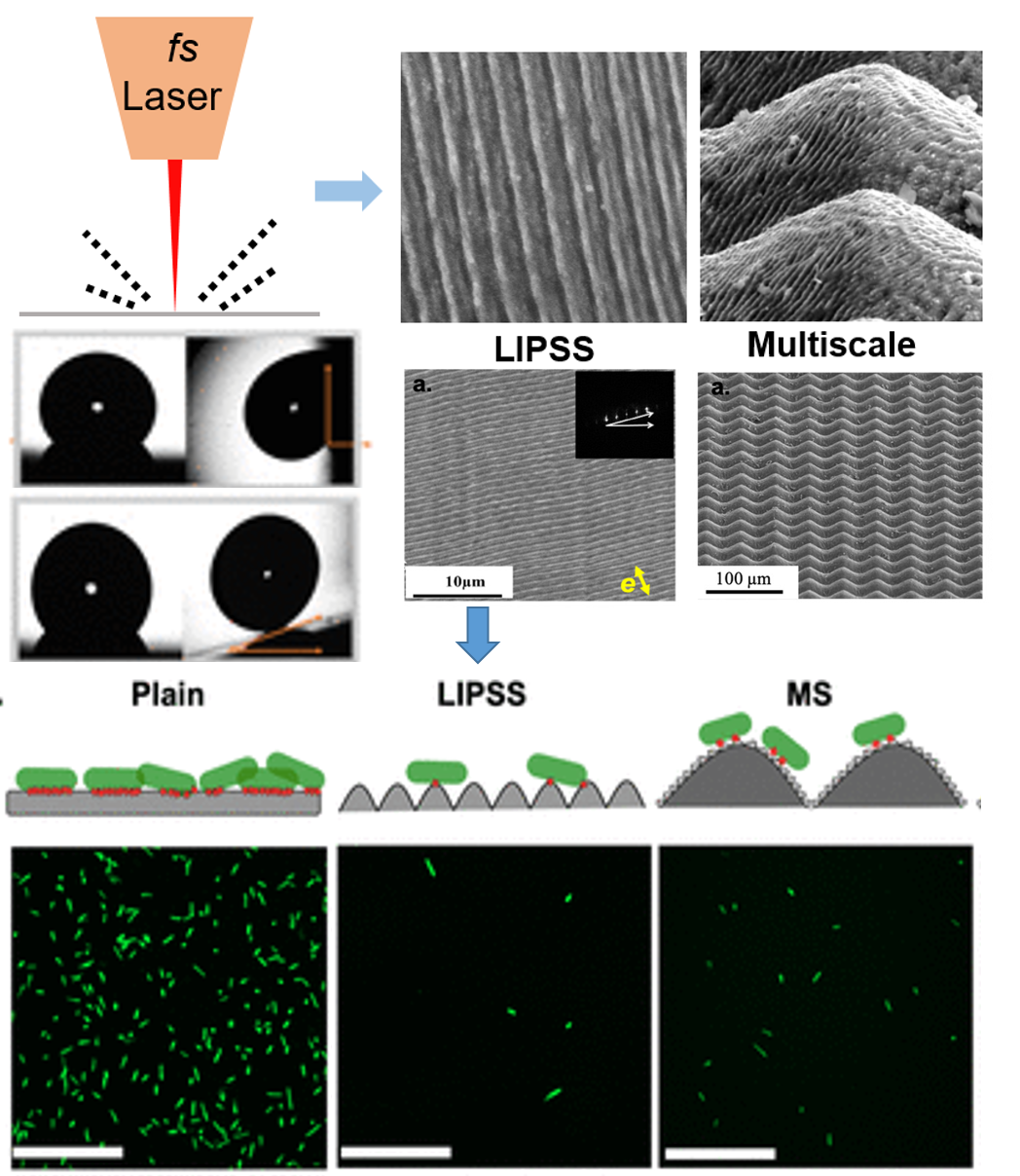

Reshma’s Ph.D topic is ‘Texturing of Bactericidal Surfaces by femtosecond lasers’. The complex nature of the bacteria cell wall interactions with nanostructured surfaces represents many challenges while the design of nanostructured bactericidal surfaces will be considered. After designing the surface, femtosecond laser will be used to fabricate the surface with the given specifications. Her research interest is bactericidal surface, femtosecond lasers. She completed her B. Tech (2011-15) and M. Tech (2015-17) from Jamia Millia Islamia University (Mechanical engineering department). reshmayasmin04@gmail.com |

|

Ratan’s Ph.D topic is ‘Texturing of plastics with application to food packaging’. Adhesion of liquid food in packaging poses issues in cleaning and recycling and incomplete utilization of products. It is, therefore necessary to understand the mechanism of interaction of liquid food with packaging surfaces. His research interest lies in Computational Fluid Dynamics and the fabrication of textured surfaces for food packaging. He received his M. Tech in Mechanical Engineering from IIT Madras in 2018, while he obtained his B. Tech in Mechanical Engineering from Vishwakarma Institute of Technology, Pune. On graduating in 2013, he joined Eaton Technologies Pvt. Ltd. as an Associate Engineer and subsequently worked as Engineer Technical Services with Design Tech. He has overall industry experience of 3 years from 2013-2016.. ratan281@gmail.com |

|

Zakir is presently a Dual Degree student (B.Tech + M.Tech) in the Mechanical Engineering department at the Indian Institute of Technology Bombay (IITB). His project topic is "Data-based modelling of damage evolution in composite materials for aerospace applications". zakirhussain@iitb.ac.in. |

|

Pramod is presently an M.Tech student Mechanical Engineering department at Indian Institute of Technology (IIT) Bombay. His M.Tech project topic is "Texturing of polymer surface to fabricate anti-fogging surface for food packaging application". kcpramod007@gmail.com |

| S.No | Name | Thesis Title | Year |

|---|---|---|---|

| 19 | Ankit Kumar | Thermal modeling of drilling titanium under various cooling strategies | 2021- Submitted |

| 18 | Yogesh Gaikhe | Modeling of machining of multi-layered composites (As Co-supervisor) | 2021- Submitted |

| 17 | Dipesh Trivedi | Microstructural analysis of drilled surfaces on titanium alloy generated using various cooling strategies. | 2021 |

| 16 | Siddharam Mane | FE based 3D Thermo-mechanical modeling of a machining process including chip-tool interface modeling | 2021 |

| 15 | Alwin Varghese | Tool life cycle monitoring using analytical and machine learning models in micro-milling | 2021 |

| 14 | Vijailaxmi | Blood plasma separation (As co-supervisor) | 2020 |

| 13 | Jithin S | Modelling and Analysis of Surface Topographies Generated using Electrial Discharge Texturing (EDT) | 2020 |

| 12 | Kamlesh Joshi | Ultra-thin Si wafer slicing using wire-EDM for photovoltaic applications | 2019 |

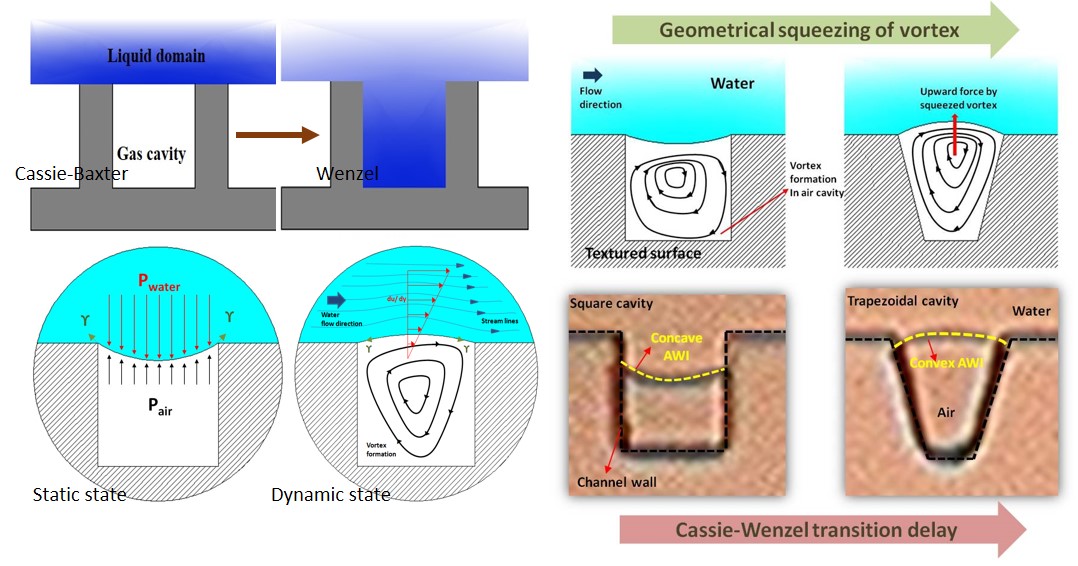

| 11 | Anvesh Gaddam | Investigations on flow-induced wetting transition and associated interfacial slip in textured micro channels | 2018 |

| 10 | Dattatraya Parle | Modeling of Size Effect in Micro-Cutting Considering Fracture and Microstructure. | 2016 |

| 9 | Piyush Tailor | Experimentations and Simulations of Eelectro-chemical Buffing (ECB) Process. | 2015 |

| 8 | Shashikant Joshi | Analysis of chip segmentation and its microstructure in machining of titanium alloys. | 2015 |

| 7 | Sachin Mastud | Development and Modeling of Reverse Micro EDM for Fabrication of High Aspect Ratio Features and Textured Surfaces. | 2014 |

| 6 | Harshad Sonawane | Modeling of Tool-work Interaction Mechanics in Ball-end Milling of Superalloy. | 2014 |

| 5 | Ganesh Dongre | Efficient Slicing of Silicon Ingots by wire-EDM process with Focus on Photovoltaic Applications | 2014 |

| 4 | Deepak Marla | Modeling of Laser Ablation of Metals for Nanosecond Pulses. | 2013 |

| 3 | P. Govindan | Process Development and Modeling of Dry Electrical Discharge Machining. | 2012 |

| 2 | Raju S. Pawade | Material deformation characteristics and machined surface integrity in high-speed turning of Inconel 718. | 2008 |

| 1 | Uday. A. Dabade | Characteristics of Machined Surfaces on Al/SiCp Metal Matrix Composites Produced during Turning. | 2008 |

| S.No | Name | Thesis Title | Degree | year |

|---|---|---|---|---|

| 116 | Shekhar | Predicting Tool breakage using Data based techniques. | D.Deg. | 2021 |

| 115 | Zeba Malik | Modellng of laser assisted surface heat treatment of Ti6Al4V alloy. | M.Tech. | 2021 |

| 114 | Sohail Ahmed | Trapping of light for photovoltaic applications. | M.Tech. | 2020 |

| 113 | Sumant Badri | Investigation on the influence of tool path radius on tool wear and tool life prediction in micro-milling using neural networks. | D.Deg. | 2020 |

| 112 | Ashish Manwar | Online Tool Condition Monitoring in Micromilling using Neural Network. | D.Deg. | 2020 |

| 111 | S Vinay Kumar | Multi-Channel Convolutional Neural Network to predict Remaining Useful Life (RUL) in gas turbine engine. | D.Deg. | 2019 |

| 110 | Anup Sharma | Laser Surface Texturing of Silicon for anti-reflection: Experimental Characterization and Optimization using FDTD simulations. | M.Tech. | 2019 |

| 109 | Pinal Rana | A study on residual stress and thermal damage in slicing of ultra-thin silicon wafers using wire-electrical discharge machining. | M.Tech. | 2019 |

| 108 | Vishnu K. P. | Numerical Simulation and Characterization of Electro Chemical Discharge Machining. | M.Tech. | 2018 |

| 107 | Zimare Anmol | Modelling and analysis of pulsed laser ablation. | M.Tech. | 2018 |

| 106 | Rohit Japtap | Simulation of the tool-chip interface in mist assisted orthogonal turning of Ti6Al4V. | M.Tech. | 2018 |

| 105 | Kamran Ullah Khan | Burr analysis in micro-milling considering tool life. | M.Tech. | 2018 |

| 104 | Ganesh Rahinj | Burr formation in drilling of Ti6Al4V. | M.Tech. | 2017 |

| 103 | Piyush Mourya | Modeling surface roughness in micro-milling. | M.Tech. | 2017 |

| 102 | Hemant Patne | Modeling and Simulation of Temperature Distribution in Drilling of Titanium. | M.Tech. | 2016 |

| 101 | Raut Ajinkya | Electric Discharge Based Surface Texturing. | D.Deg. | 2015 |

| 100 | P. Sastry Akella | Front Contact Patterning for Metallization of c-Si Solar Cells. | M.S. | 2015 |

| 99 | Khandagale Pratik | Modelling the vibratory response of materials with thin rectangular geometry in machining. | D.Deg. | 2015 |

| 98 | Ashwin Prabhakaran | Deformation based Texturing of Large Areas Using Rolling. | M.Tech. | 2015 |

| 97 | Vipul Agrawal | Wear Analysis and Tool Life Modelling In Drilling Inconel 718. | M.Tech. | 2015 |

| 96 | Varote Nilesh Vilas | Modeling of machined surface integrity in drilling of Ti alloy. | M.Tech. | 2015 |

| 95 | Amal S. Siju | Cutting tools with microscale textures on rake face to improve frictional Behaviour. | M.Tech. | 2015 |

| 94 | Sonawane Harshad | Modeling of Tool-work Interaction Mechanics in Ball-end Milling of Superalloy. | MTech. | 2014 |

| 93 | Rana Ankit S | Modelling mechanics of burr formation to predict exit burr size in drilling Ti6Al4V. | D.Deg. | 2014 |

| 92 | Aditya P Desai | Modelling of Lateral Wire Vibrations in Wire EDM through Balance of Discharge Forces. | D.Deg. | 2014 |

| 91 | Sahu Shailesh | Modelling of temperature distribution leading to evaluation of shear band width in machining of Ti6Al4V. | D.Deg. | 2014 |

| 90 | Wanaskar Kapil P | Analysis of machining stability in flank milling of impeller blades with decreasing thickness. | D.Deg. | 2014 |

| 89 | Bharath K S | Experimental and numerical study of flow over textured surface. | M.Tech. | 2014 |

| 88 | Kekade Swapnil V | Effect of parameters on dimensional accuracy in CBN grinding of forged crankshafts. | M.Tech. | 2014 |

| 87 | Nikesh Nayak | Experimental analysis of high speed drilling of Inconel 718 using coated carbide drills. | M.Tech. | 2014 |

| 86 | Narendra Singh | Analysis of Machining Stability in Flank Milling of Impeller Blades. | M.Tech. | 2014 |

| 85 | Khushboo S. | Design and Development of Compliant Based Microgripper Assembly Station. | M.Tech. | 2014 |

| 84 | Ankita Agrawal | Experimental and Numerical Analysis of workpiece stability in flank milling of Ti6Al4V. | M.Tech. | 2014 |

| 83 | Pawar Omanath | A Analysis of hole quality in drilling of fiber metal laminates (FMLs)-GLARE 5 & 6. | M.Tech. | 2014 |

| 82 | Ranjan Das | Modeling and analysis of tool wear in drilling. | M.Tech. | 2014 |

| 81 | Pawar Swapnil V | Study on Vibration-assisted Tapping of Titanium alloy. | M.Tech. | 2014 |

| 80 | Hiremath P C | Effect of microstructure & hardness after heat treatment on machinability of steel forgings. | M.Tech. | 2014 |

| 79 | Deshmukh Vinod R | Chemical milling for alpha case removal in titanium alloy. | M.Tech. | 2014 |

| 78 | Ingle Ajay Jivanram | Parametric analysis of plunge cylindrical grinding on crankshaft. | M.Tech. | 2014 |

| 77 | Thanedar Azher | Analysis of grinding burns using BNA value optimization. | M.Tech. | 2014 |

| 76 | Abhinav Solanki | Modeling and Simulation of Tapping of Titanium. | D.Deg. | 2013 |

| 75 | Ramchandani Jai S. | Modeling tool chip interface for oil mist assisted orthogonal turning of Ti6Al4V. | D.Deg. | 2013 |

| 74 | Gaurav Sharma | Modeling of Wire EDM Slicing Process for Silicon Ingots. | D.Deg. | 2013 |

| 73 | Shubham Gupta | Modeling of Shear Bands and Specific Cutting Energy in Ti6Al4V alloy. | D.Deg. | 2013 |

| 72 | Shinde Sagar S | Modeling of twist drilling process of Ti-6Al-4V alloy to predict hole quality. | MTech. | 2013 |

| 71 | Sarvaiye Amit kumar | Numerical simulation of flow over textured surfaces. | M.Tech. | 2013 |

| 70 | Vivek Garg | Numerical Modeling of Excimer Laser Curved Surface Ablation. | M.Tech. | 2013 |

| 69 | Vinod Singh Rajput. | Experimental investigation of elecrochemical buffing. | M.Tech. | 2013 |

| 68 | Sumeet Jain S. | Vibration Analysis in High Speed Milling of Inconel 718. | M.Tech. | 2013 |

| 67 | Patil Rahul A | Analysis of burr formation in drilling of Ti-6Al-4V. | M.Tech. | 2013 |

| 66 | Vikalp Jambhulkar | Sari Cutting Machine for Mat Making Handloom. | D.Deg. | 2012 |

| 65 | Abhishek Gupta | Mathematical Modeling of magnetic field effect on dry EDM. | D.Deg. | 2012 |

| 64 | Kulkarni Anish Ajit | Modeling of Laser Ablation and Fabrication of Microstructures. | D.Deg. | 2012 |

| 63 | Ranjit Kumar | Modeling of Super hydrophobic surfaces for bulk flow. | D.Deg. | 2012 |

| 62 | Lakhani Harnish | Modelling of microstructural change during machining of Ti6Al4V. | M.Tech. | 2012 |

| 61 | Patil Nitin R | Numerical Modeling of Laser Sintering Process. | M.Tech. | 2012 |

| 60 | Bhalerao Nitin B | High Strain Rate Behavior of Ti-6Al-4V Alloy and Machining Characteristics. | M.Tech. | 2012 |

| 59 | Ratendra Kumar | Experimental Investigation On Electro-chemical Buffing. | M.Tech. | 2012 |

| 58 | Aswin. P | Modeling of Wire-EDM slicing of silicon ingots. | M.Tech. | 2012 |

| 57 | Sandip P Patil | Ultrasonic vibration assisted machining of titaniumTi-6Al-4V. | M.Tech. | 2012 |

| 56 | Pravin S Pawar | Comparison of machinabilities of Alpha, Alpha + Beta; and Beta rich Alpha+Beta titanium alloys in orthogonal turning. | M.Tech. | 2012 |

| 55 | Devansh Sharma | Development of Leader-Follower Robots. | D.Deg. | 2011 |

| 54 | Prashant Kumar | Design and Development of Conformal Hydrodynamic Nanopolishing Machine and Process for Polishing Single Crystal Sapphire. | D.Deg. | 2011 |

| 53 | Vesvikar Cyrus | Mathematical modeling of wire EDM cutting of Si ingots for PV applications. | D.Deg. | 2011 |

| 52 | Mayank Garg | Numerical Simulation of Bulk Flow Over Textured Surfaces. | D.Deg. | 2011 |

| 51 | Akshay Shrivastava | Process characterization of Reverse Micro EDM. | D.Deg. | 2011 |

| 50 | Yogendra K Meena | Prototype Sari Cutting Machine for Handlooms Operated by Visually Disabled Individuals. | D.Deg. | 2011 |

| 49 | Jagdish P Meena | Fabrication of PDMS Arrayed Micro structures Using Silicon Etching-LIGA. | D.Deg. | 2011 |

| 48 | G Aanand Pratik | Development of Microneedles by Electro-deposition and -forming. | M.Tech. | 2011 |

| 47 | Prashant Thakur | Numerical Simulation and Characterization of Electrochemical Buffing. | M.Tech. | 2011 |

| 46 | Saurabh Agrawal | Analytical Modeling of Residual Stresses in Orthogonal Machining of AISI4340. | M.Tech. | 2011 |

| 45 | Dake Pritamkumar | Pulsed Laser Ablation: Numerical Simulation and Analysis. | M.Tech. | 2011 |

| 44 | Jyoti Shankar Jha | Numerical Simulation of Micro Hot Embossing Process. | M.Tech. | 2011 |

| 43 | Sachin Mali | Simulation of staggered flow forming process. | M.Tech. | 2011 |

| 42 | Shinde Shreyas R | Determination of machinability of steel & important parameters in steel making & machining. | M.Tech. | 2011 |

| 41 | Rinku Kumar Mittal | Characterization and Modeling of Hydrodynamic Nanopolishing Process. | D.Deg. | 2010 |

| 40 | Prithvi Raj | Design and Fabrication of Super-Hydrophobic Surface for Single-Droplet. | D.Deg. | 2010 |

| 39 | Kadam Girish S | Modeling of Single-Discharge in Dry Electrode Discharge Machining. | D.Deg. | 2010 |

| 38 | Ashish Mall | Design and Fabrication of Superhydrophobic Surfaces for Bulk Flow. | D.Deg. | 2010 |

| 37 | Bagale Tammaraya | Finite element modeling of pulsed laser ablation. | M.Tech. | 2010 |

| 36 | Sudhir SMore | Hdrodynamic nanopolishing set up and process for super polishing of hard materials. | M.Tech. | 2010 |

| 35 | Kurundkar Onkar A | Analytical modeling of residual stresses in Inconel 718 by ball end milling. | M.Tech. | 2010 |

| 34 | Tamrat A. Gelu | Behavior of materials under high strain rate shear loading. | M.Tech. | 2010 |

| 33 | Mrinal Joshi | Hydrodynamic Polishing of Hardened Steels. | D.Deg. | 2009 |

| 32 | Nikhil Jain | A Statistical Approach for Integrating Analytical and FEM in Micromachining Applications. | D.Deg. | 2009 |

| 31 | Kaushik J | Development of a vision-based microassembly system. | D.Deg. | 2009 |

| 30 | Ashish A Kullu | Modeling of ablation depth on ceramics in excimer laser micromachining. | D.Deg. | 2009 |

| 29 | Anand R Wankhede | Feasibility of Producing Multilayer Part By Metal Injection Moulding. | M.Tech. | 2009 |

| 28 | Vasantgadkar Nikhil | Development of Pulsed Laser Deposition system using Excimer laser. | M.Tech. | 2009 |

| 27 | Raut P Brahmadeo | Excimer laser-LIGA: Numerical simulation of micro hot embossing process. | M.Tech. | 2009 |

| 26 | Lekkala Ravi | Modeling and Analysis of Burrs in Micro Milling. | M.Tech. | 2009 |

| 25 | Parag Saharia | Design and Development of Milling Cutter with Self-Propelled Round Inserts. | D.Deg. | 2008 |

| 24 | Ishan Saxena | Fabrication of micro-filters using excimer laser micromachining. | D.Deg. | 2008 |

| 23 | Ramkesh Meena | Excimer Laser-LIGA: Design and Fabrication of Hot Embossing setup. | D.Deg. | 2008 |

| 22 | Dilip H Dapkekar | Analytical Modelling for Cutting Forces in End Milling of Metal Matrix Composites. | M.Tech. | 2008 |

| 21 | Dheeraj Ahluwalia | Design and Development of Micro-electrodeposition Process for Laser-LIGA. | M.Tech. | 2008 |

| 20 | Amit Srivastava | Modeling of ablation process in excimer laser micromachining. | D.Deg. | 2007 |

| 19 | Saradindu Das | Modeling of spark-erosion rate in micro-WEDM. | D.Deg. | 2007 |

| 18 | Vishal Barde | Modeling of Ablation Process in Excimer Laser Micromachining. | M.Tech. | 2007 |

| 17 | Prasanna D. Sapre | Development and modeling of micro-electrochemical grinding (micro-ECG) process. | M.Tech. | 2007 |

| 16 | Jason Balou | Burr formation in Cross-holes in MADI alloy (At UIUC, USA). | M.S. | 2006 |

| 15 | Antariksh R P Singh | Improving accuracy and aspect ratio of micro-EDM process. | D.Deg. | 2006 |

| 14 | Gaurav Tandon | Development of an Active Roll Control system. | D.Deg. | 2005 |

| 13 | M.P.S. K. Kiran | Modeling of Micro-Electrical Discharge Machining. | D.Deg. | 2005 |

| 12 | Kishore S. Gaikwad | Development and analysis of electrochemical grinding for micro-machining. | M.Tech. | 2005 |

| 11 | Thao Oliever | HAZ in micro-EDM (A higher degree student from France). | M.S. | 2005 |

| 10 | Manish S. Puranik | Development and modeling of micro-EDM to generate high aspect ratio features. | M.Tech. | 2005 |

| 9 | Suyog S Zende | Analysis and Modeling of Hybrid Compoistes using FEM. | M.Tech. | 2005 |

| 8 | Berhanu Girma M | Optimization of Magnetic Abrasive Machining Process. | M.Tech. | 2004 |

| 7 | Sandeep Dhanik | Modeling of Micro-EDM process for Micro-Machining. | D.Deg. | 2004 |

| 6 | Abeesh C Basheer | Modeling of machining process in metal matrix composites using ann. | D.Deg. | 2004 |

| 5 | Pradeep Dixit | Development of Electrochemical MIcromachining Setup. | M.Tech. | 2003 |

| 4 | Kaushikkumar Patel | Mechanics of machining using self-propelled round insert milling cutter. | M.Tech. | 2003 |

| 3 | G. V. S. Raghuram | Parametric Studies and Modeling of Magnetic Abrasive Finishing. | M.Tech. | 2002 |

| 2 | Dattatray Pendse | Process Modeling and Optimization of Composite Machining using ANN. | M.Tech. | 2002 |

| 1 | Dabade Udaykumar | Design and Development of Miling Cutter with Self-propelled Round Inserts. | M.Tech. | 2002 |

| S.No. | Project Name | Sponsor | Budget | Year |

|---|---|---|---|---|

| 1 | Generating Functional Quality Surfaces using Electrical Discharge Machining for Biomedical and Machining Applications | Expert Advisory Committee (EAC) on Advanced Manufacturing Technologies of Technology Systems Development Programme (TSDP) of DST |

Rs. 76 Lakhs (94k UK£) | 2016-19 |

| 2 | Investigation of tool-workpiece interaction in high speed drilling of titanium alloys to enhance the hole quality | Aeronautical Research and Development Board (ARDB) | Rs. 35 Lakhs (43k UK£) | 2016-19 |

| 3 | Investigation of tool-workpiece interaction in high speed drilling of titanium alloys to enhance the hole quality | Department of Science and Technology, Govt. Of India. | Rs. 33.71 Lakhs (42k UK£) | 2015-18 |

| S.No. | Project Name | Sponsor | Budget | Year |

|---|---|---|---|---|

| 1 | National Centre for Aerospace Innovation and Research (NCAIR) | Department of Science and Technology, Govt. of India, the Boeing Company and Indian Institute of Technology Bombay (India) |

Rs. 35 Cr (4300k UK£) | 2009-14 |

| 2 | Establishing Micromachining and Micrometrology Facility at IIT Bombay | Indian Institute of Technology Bombay (India) | Rs.1.88 Cr. (232k UK£) | - |

| 3 | Establishment of ‘DST-FIST Sponsored Precision Prototyping Facility’ | Department of Science and Technology, Government of India | Rs. 1 Cr (123k UK£) | 2003-08 |

| 4 | Establishment of Suman Mashruwala Micro-engineering Laboratory including the establishment of excimer laser facility | Alumnus, Indian Institute of Technology Bombay (India) | Rs. 1.25 Cr (155k UK£) | 2004-05 |

| 5 | Renovation and Modernization of Machine Tools and Metrology Laboratory and establishment of ‘Micromachining Cell’ in the laboratory | Indian Institute of Technology Bombay (India) | Rs. 70 Lakhs (86k UK£) | 2003-13 |

| S.No. | Project Name | Sponsor | Budget | Year |

|---|---|---|---|---|

| 1 | Design and fabrication of 3D Micro-textured Hydrophobic Geometries on Metallic Surface: Part – II | ISRO, Govt. of India | Rs. 22 Lakhs. (27k UK£) | 2013-15 |

| 2 | Efficient Dicing of Silicon Ingots by wire EDM | Ministry of New and Renewable Energy, Govt. of India, under the aegis National Center for Photo-Voltaic Research and Education, IIT Bombay |

Rs. 1.00 Cr. (123k UK£) | 2011-14 |

| 3 | Analysis and Modeling of Electro-chemical Buffing Process | CSIR, Govt. of India. | Rs. 15 Lakhs. (31k UK£) | 2011-13 |

| 4 | Cutting machine for visually challenged individuals for house-hold mat weaving handlooms PSA | Department of Science and Technology, Govt. Of India | Rs. 1.63 Lakhs (2k UK£) | 2012 |

| 5 | Simulation of Flow Forming Process | ISRO, India | Rs. 10 Lakhs (12.3k UK£) | 2010-12 |

| 6 | Modeling and Development of Novel EDM Variants for Micromachining | Department of Science and Technology, Govt. of India | Rs. 33 Lakhs. (40.6k UK£) | 2009-12 |

| 7 | Generation of 3D Microstructures on Metallic Surfaces using Micromachining : Part-I | ISRO, Govt. of India | Rs. 26.10 Lakhs. (32k UK£) | 2008-09 |

| 8 | Study and Development of Technology for Nano-polishing of Single Crystal Semi-spherical Cavity and Fabrication of Micro-metallic Fluidic Structures | Bhabha Atomic Research Center, Mumbai, Government of Indiaa | Rs. 65 Lakhs. (80k UK£) | 2008-09 |

| 9 | Development of Fibre Laser-based manufacturing technology for micromachining | BDepartment of Science and Technology, Govt. of India | Rs. 40 Lakhs. (49.2k UK£) | 2009-12 |

| 10 | Analysis of machined surface quality of Inconel 718 in milling operation | Aeronautical Research and Development Board, Govt. of India | Rs. 31 Lakhs. (38.1k UK£) | 2008-11 |

| 11 | Process capability analysis of micro-machining processes and development of traveling micro-mechanisms | Bhabha Atomic Research Center, Mumbai, Government of India | Rs. 30 Lakhs. (36.9k UK£) | 2004-07 |

| 12 | Micro-machining using electrochemical and electrochemical grinding processes | Ministry of Human Resources and Development, Govt. of India | Rs. 12 Lakhs. (14.8k UK£) | 2001-05 |

| 13 | Analysis and Development of Micro-EDM for Micro-machining | Department of Science and Technology, Govt. of India | Rs. 19.60 Lakhs. (24.1k UK£) | 2003-06 |

| S.No. | Project Name | Sponsor | Budget | Year |

|---|---|---|---|---|

| 1 | Design and manufacturing aspects of water filters | Tata Chemical, India Ltd., Mumbai | Rs. 5.00 Lakhs. (6.2k UK£) |

2012-13 |

| 2 | Design and manufacturing aspects of new cutting tools | Forbes India Ltd. Mumbai | Rs. 1.0 Lakhs (1.23k UK£) |

2012-13 |

| 3 | Simulation of Single crystal silicon wafer dicing using wire-EDM | Applied Materials, Ltd. India | Rs. 9.69 Lakhs. (11.8k UK£) |

2012-13 |

| 4 | Single crystal silicon wafer dicing using wire-EDM | Applied Materials, Ltd. India | Rs. 9.69 Lakhs. (11.8k UK£) |

2011-12 |

| 5 | Machinability studies on Powder Metallurgy alloyed bearing caps | Hoganas India Ltd., Pune | Rs. 6 Lakhs. (7.4k UK£) |

2010 -13 |

| 6 | Comparative evaluation of bearings | NRB Bearings, India, Ltd. Mumbai India | Rs. 2.69 Lakhs. (3.3k UK£) |

2012 |

| 7 | Design for Manufacture of ELR mechanism | Bond Safety Belt, Pvt. Ltd. Mumbai, India | Rs. 6.50 Lakhs. (8k UK£) |

2008-09 |

| 8 | First SERC School on Micromachining | Department of Science and Technology, Govt. of India | Rs.10 Lakhs. (12.3k UK£) |

2007-08 |

| 9 | Precision machining of components | Mechvac Fabricators (India) Pvt. Ltd., Mumbai, India | Rs. 4 Lakhs. (4.9k UK£) |

2004-06 |

| 10 | Design of Track Shoe using advanced composites | VRDE, DRDL,India | Rs. 2.50 Lakhs. (3.08k UK£) |

2004-05 |