Advanced Manufacturing

Processes Lab (AMPL)

Processes Lab (AMPL)

AMPL

Digital manufacturing integrates advanced technologies to enhance precision and efficiency. Robotic arc welding, guided by image processing and photogrammetry, enables precise welding along complex path geometries. Closed-loop control systems regulate welding speed in real-time, ensuring uniform heat distribution, minimizing defects, and optimizing material usage. This approach enhances dimensional accuracy and improves repeatability. By combining robotics, adaptive control and sensor feedback, convergent manufacturing streamlines production, reduces lead times, and enables high-precision welding for industrial applications.

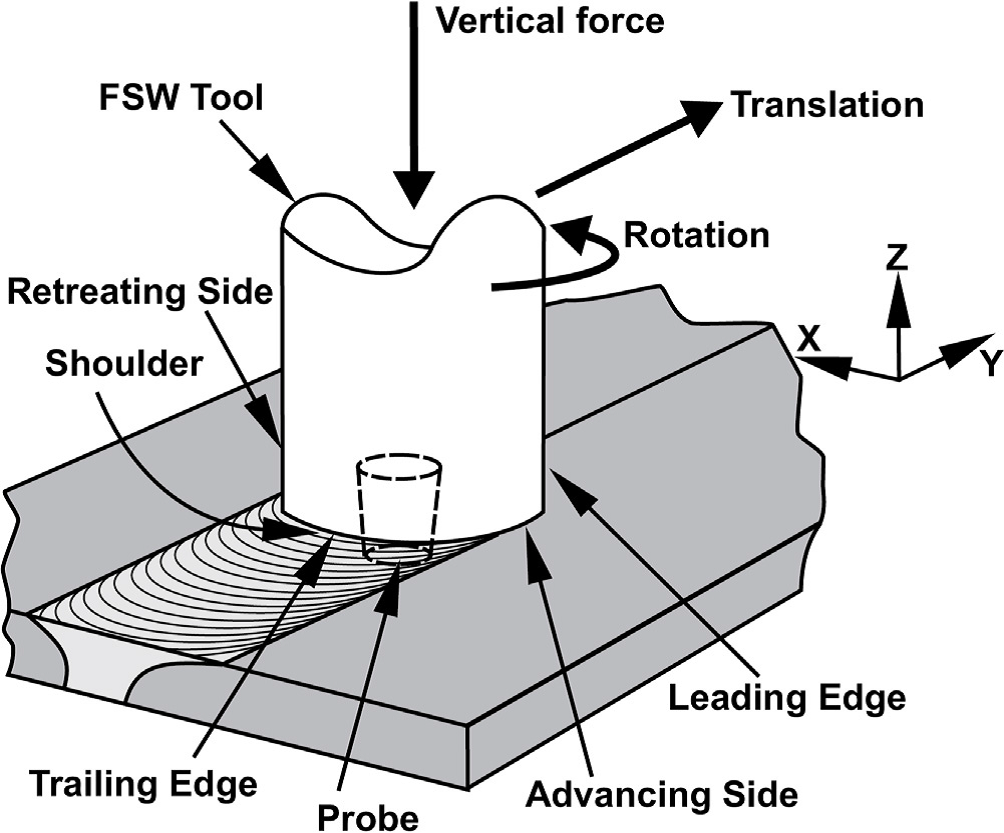

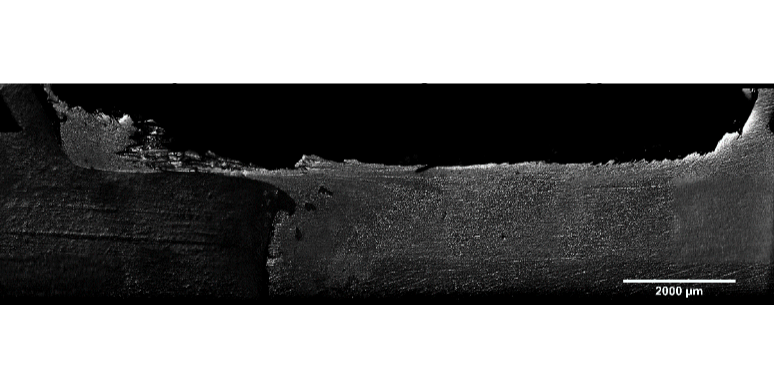

Friction stir welding (FSW) is a solid state joining technique. During FSW, workpieces are plastically deformed and mechanically intermixed under mechanical pressure at elevated temperatures. However, these joints are created below the solidus temperature of the workpiece. The ability of FSW process to join materials without melting allows the venues for welding/joining of dissimilar materials. The objective of this project is to investigate and model material mixing, intermetallic compound formation and diffusion during friction stir welding of dissimilar materials.

Department of Science & Technology

Hybrid Laser Arc Welding (HLAW) combines laser welding's precision with arc welding's high deposition rate, enabling deep penetration, faster processing, and enhanced productivity. It reduces passes, minimizes heat-affected zones (HAZ), and improves weld stability, gap bridging, and sidewall fusion. Adaptive control allows real-time parameter adjustments to counter material and environmental variations, ensuring consistent weld quality and precise deposition while reducing defects and post-processing. This work aims to develop an adaptive control strategy for automatic parameter adjustment to address fit-up variations, achieve desired penetration depth, and minimize HAZ, reducing thermal residual stress and distortion in hybrid welded joints.

Joints of dissimilar materials provide venues for light weighting in many applications. Intermetallic compounds are inevitable in dissimilar material joints. The fatigue and fracture characteristics of dissimilar joints are of particular interest for the applications where joints are subjected to cyclic loading. The nature of intermetallic compound and its distribution determines the fatigue performance of the joint. The objective of this work is to map the intermetallic compound formation to the joining process parameters and to correlate the nature and distribution of compounds to the fatigue behaviour of the dissimilar joints.

Prof. Wenyi Yan, Monash University, Australia

IITB-Monash Research Academy

Rotary friction welding is a solid-state process, used for joining of cylindrical workpieces. This work focuses on developing joints of dissimilar materials for aerospace applications. During the process, base materials are subject to high temperatures and stresses, which lead to the formation of intermetallic compounds at the joining surfaces. These compounds may adversely affect the joint performance. This work explores the usage of interlayers for limiting the detrimental intermetallics in dissimilar joints and aims to achieve joints with improved mechanical characteristics.

Dr. SGK Manikandan, IPRC

Indian Space Research Organization

The work is focused on additive manufacturing with Titanium alloys and Inconel alloys. Currently, the interest is in understanding the effect of scanning strategies on the mechanical properties of the resulting deposits. Numerical tools are developed to predict the heat transfer, fluid flow and thermal history-based phase transformation during the process. Further investigations are underway to establish the structure-property relationships for the resulting deposits.

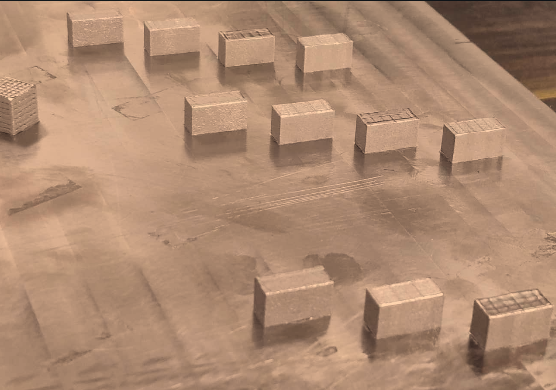

Wire Arc Additive Manufacturing (WAAM) is an arc-based AM process where filler wires are deposited over a substrate with Gas Metal Arc Welding, Gas Tungsten Arc Welding, or Plasma Arc Welding systems in a layer by layer fashion to build and create parts. WAAM is a significantly faster, more productive, and more efficient metal additive manufacturing process compared to its powder-based peers. Robotic WAAM is emerging as one of the major technologies for building and repairing large parts. The objective of this work is to investigate the dimensional accuracy of the WAAM process with a novel in-situ computer vision system.

| Project Title | Duration | Sponsoring Agency |

|---|---|---|

| Process modeling & microstructural evolution during friction stir welding of dissimilar materials | 2017-21 | DST Early Career Research Award |

| Friction stir welding of dissimilar materials | 2017-21 | IIT Bombay |

| X-ray based Online Measurement Methods | 2019-20 | Puretronics India |

| Vacuum Brazing of SS 321 and Silver components | 2018-19 | Brahmos Aerospace Private Limited |

| Automation of Cable Manufacturing Process | 2017-19 | TE Connectivity India Private Limited |

| Liquified Petroleum Gas Transfer | 2018-18 | Bharat Petroleum Corporation Limited |

| Development of Magnetic Drilling Machine | 2016-18 | BroachCutter Drilling Machines Private Limited |