Laser Advanced

Materials Processing Lab

Pioneering research in laser-based manufacturing and advanced materials processing technologies

About Us

The Laser Advanced Materials Processing (LAMP) Laboratory at IIT Bombay focuses on cutting-edge research in laser-based manufacturing processes. Our team is dedicated to pushing the boundaries of advanced materials processing through experimental and computational approaches.

Under the leadership of Prof. Deepak Marla, our laboratory investigates fundamental aspects of laser-material interactions, develops advanced computational models, and explores innovative applications in various industries.

Learn More About Our TeamLAMP Lab Research

-

Laser Materials Processing and Micromachining

-

Laser-Matter Interaction

-

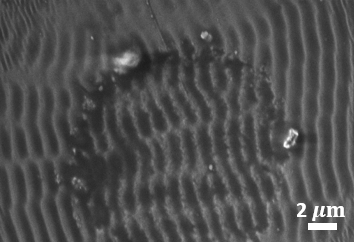

Surface Modification & Texturing

-

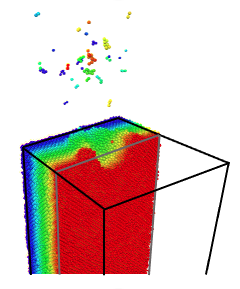

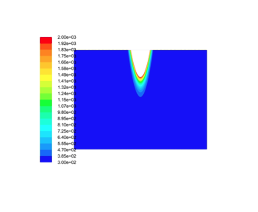

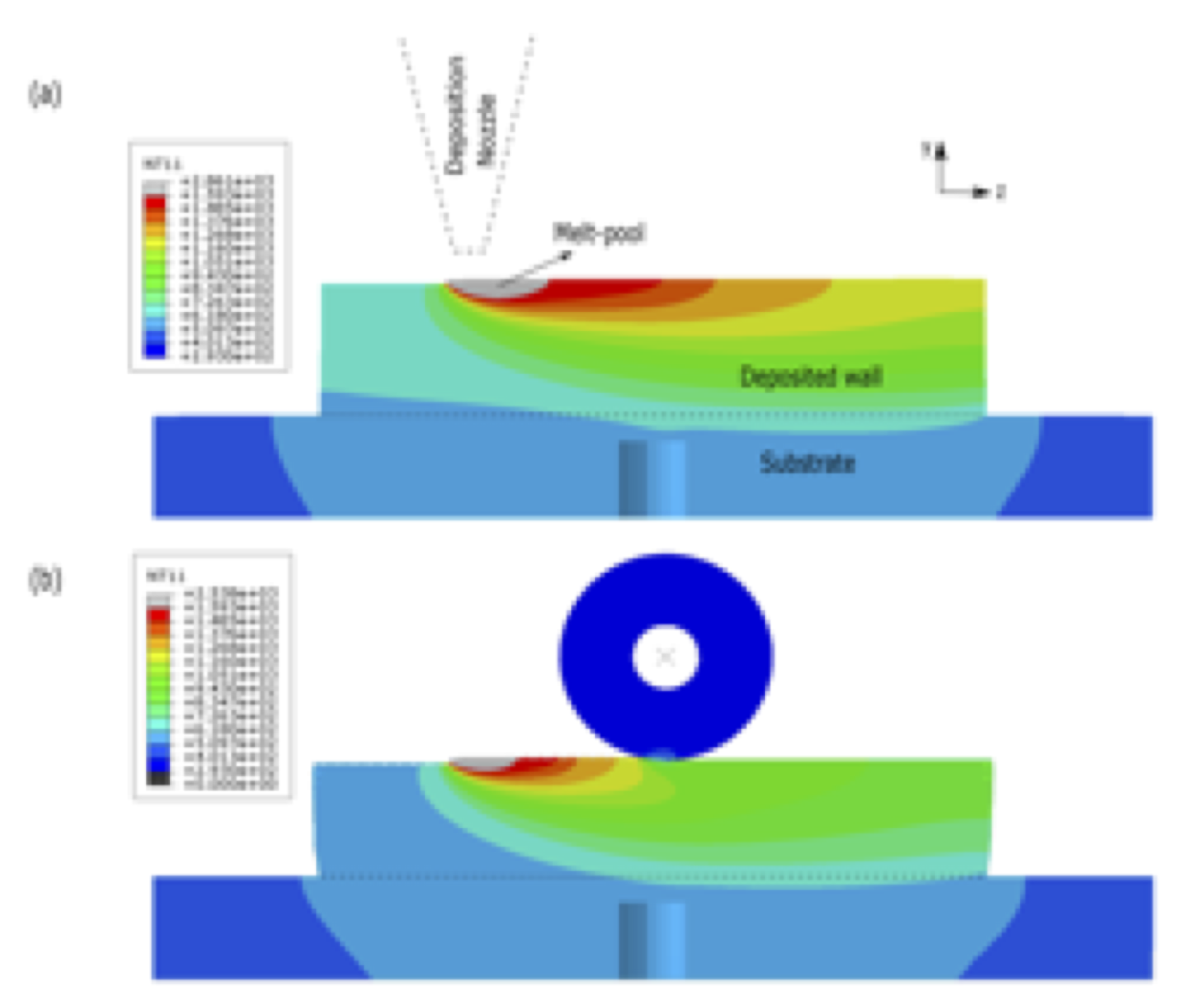

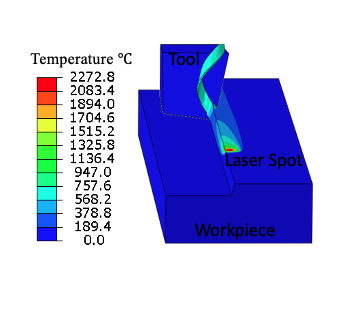

Multi-physics Modeling

-

Multi-physics Simulations

Lab Incharge

Prof. Deepak Marla

Associate Professor

Prof. Deepak Marla is an Associate Professor in the Department of Mechanical Engineering at Indian Institute of Technology Bombay. His research interests include laser materials processing, computational modeling of manufacturing processes, and experimental investigation of thermo-physical processes.

Visit Personal WebsiteOur Facilities

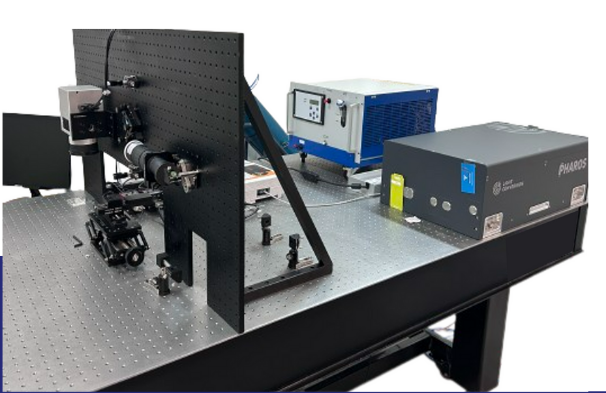

Femtosecond Laser

Ultrafast femtosecond laser for precision micromachining applications

View Details

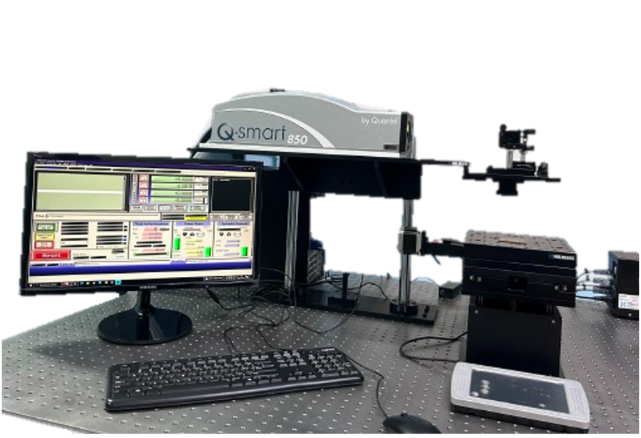

NdYAG Nanosecond Laser

High-power nanosecond laser system for material processing and research

View Details

Fibre Nanosecond Laser

Advanced fibre laser technology for efficient and precise material processing

View DetailsResearch Areas

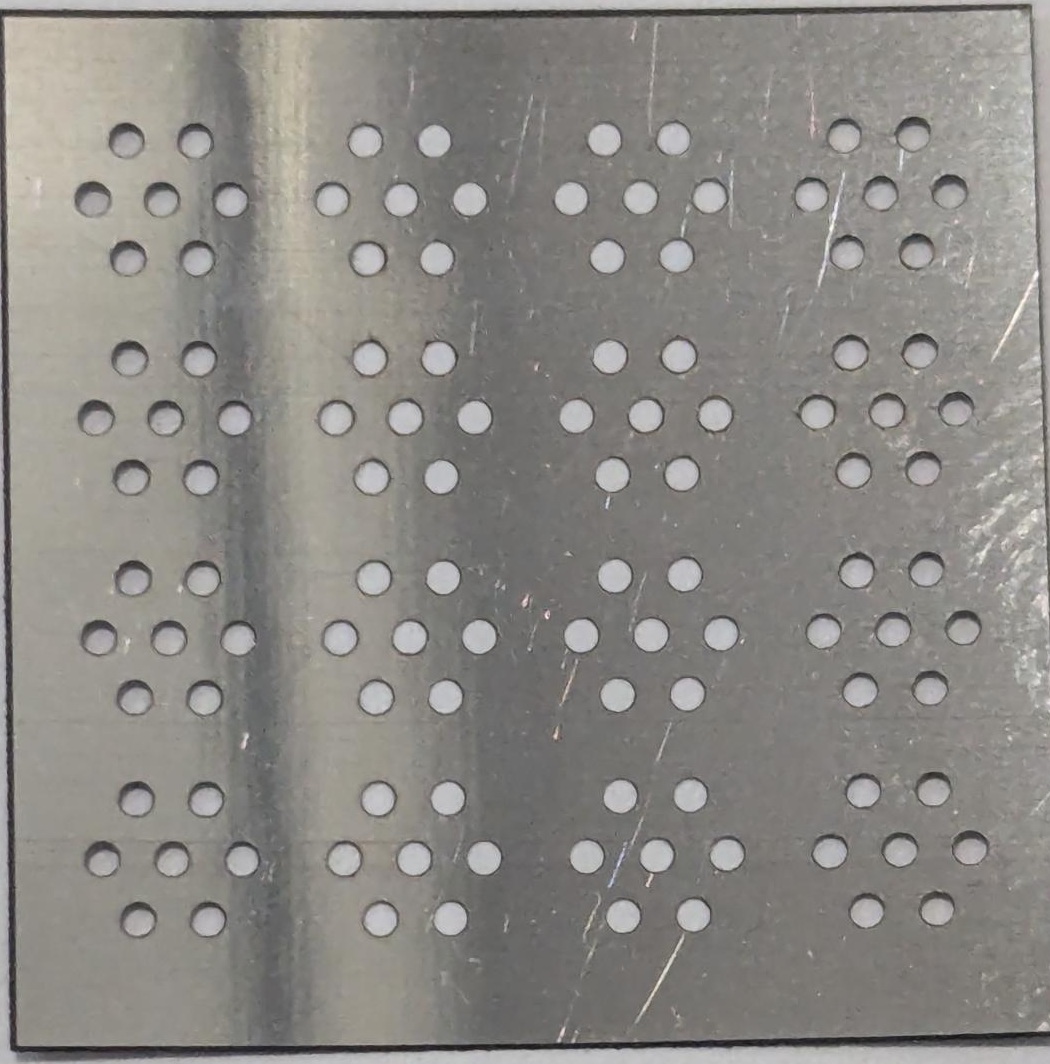

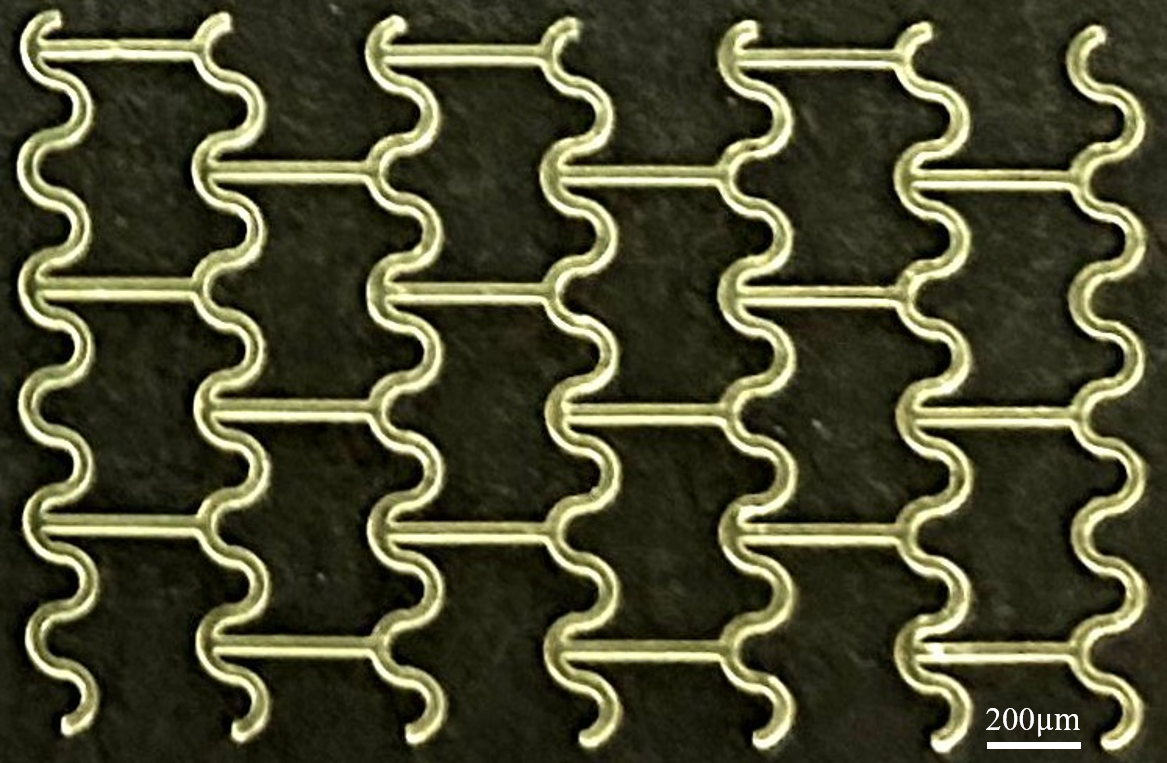

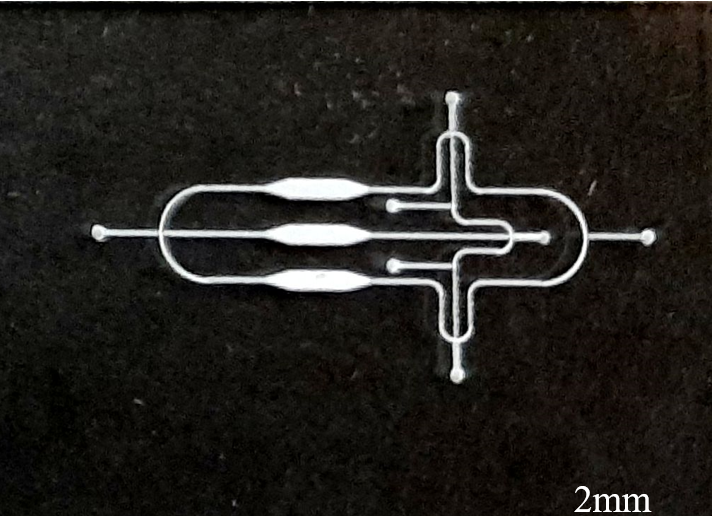

Laser Microfabrication

LAMP Lab (Laser Applications and Materials Processing Lab) is a multidisciplinary research group dedicated to advancing precision material processing at micro and nano scales. The team explores cutting-edge interactions between light and matter, enabling high-resolution structuring, patterning, and modification of diverse materials. Their work combines theoretical modelling, experimental techniques, and application-driven innovations to develop solutions for electronics, photonics, biomedical devices, and material science. With a strong focus on ultrafast optics, phase transformations, and non-linear effects, LAMP Lab continues to push the boundaries of optical processing technologies.

Research in this area focuses on developing novel methods for fabricating microchannels, textures, and functional features on different materials including metals, ceramics, and polymers.

Learn More