Research Overview

Modeling & Simulation

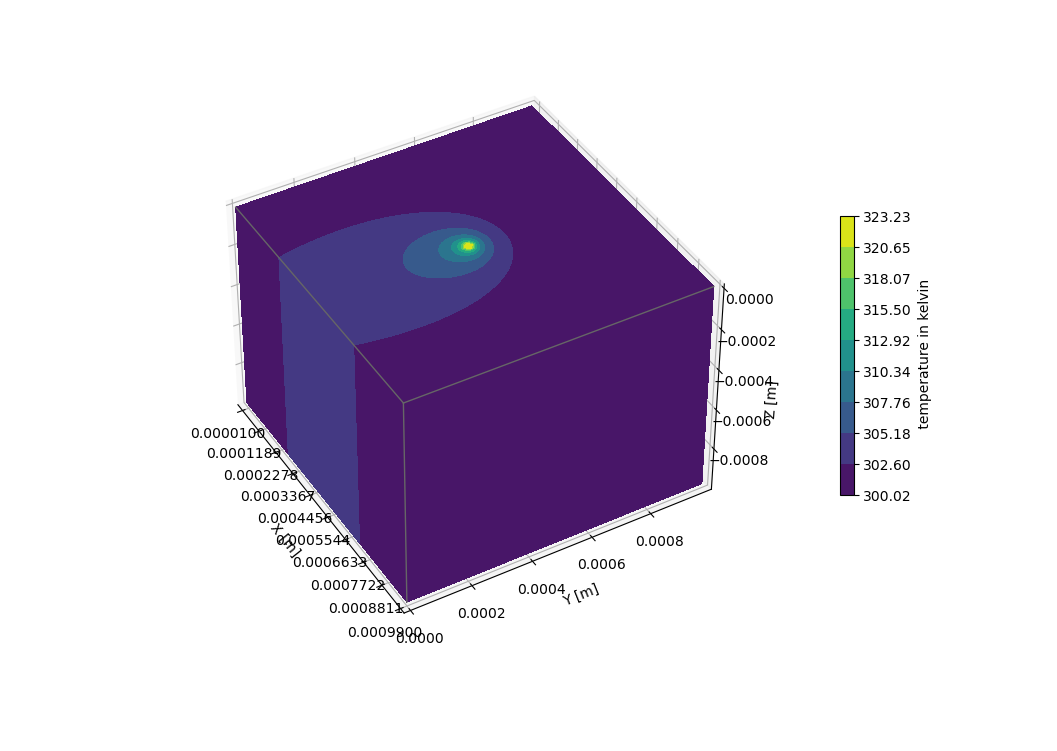

Multi-scale computational modeling of laser-material interaction

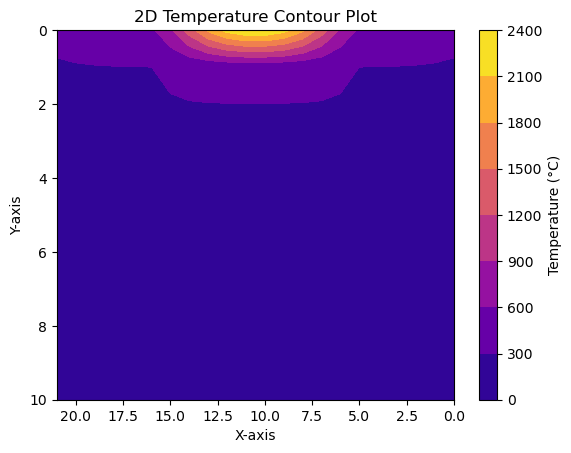

Our research in modeling and simulation focuses on developing multi-scale computational models to understand the complex physical phenomena in laser-material interactions. These models help in predicting material behavior, optimizing process parameters, and developing next-generation laser processing techniques.

Research Highlights

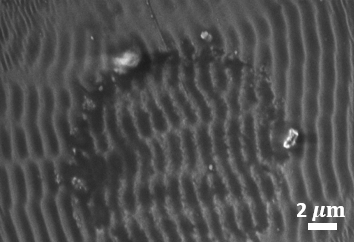

- Molecular Dynamics Simulations of femtosecond laser–matter interactions reveal atomic-level mechanisms of energy absorption, phase transitions, and material removal in ultrafast regimes.

- Finite Difference Methods are employed to solve the two-temperature heat transfer model, capturing the nonequilibrium thermal dynamics between electrons and lattice in ultrafast laser processing.

- Computational Fluid Dynamics (CFD) models simulate laser ablation and drilling processes, enabling insights into melt flow, vapor recoil pressure, and plume dynamics.

- Finite Element Modeling (FEM) of laser-directed energy deposition captures the coupled thermo-mechanical response during additive manufacturing and surface modification.

- FEM-based Thermo-Mechanical Modeling of laser-assisted machining elucidates the role of laser preheating on cutting forces, chip formation, and surface quality.

- FEM-based Modeling of femtosecond laser welding of glass-glass and glass-metal interfaces investigates localized melting, stress evolution, and interfacial bond formation under ultrashort pulse irradiation.

Research Projects

Femtosecond Laser Welding of Glasses

2025 - Ongoing

Femtosecond laser welding of glasses enables precise, high-strength bonding with minimal thermal damage due to ultrashort pulse durations. Our research focuses on understanding the interaction mechanisms and optimizing process parameters for robust and crack-free welds. The approach is ideal for advanced photonic and microfluidic device fabrication.

Machine Learning for Smart Laser Color Marking

2021 - Present | Funded by DST

Our research leverages machine learning to enable smart laser color marking by predicting optimal process parameters based on material properties and desired hues. By training models on experimental data, we achieve high-precision color control on metal surfaces with minimal trial-and-error. This data-driven approach enhances efficiency, consistency, and customization in laser-based aesthetic and functional surface treatments.

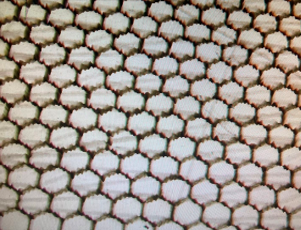

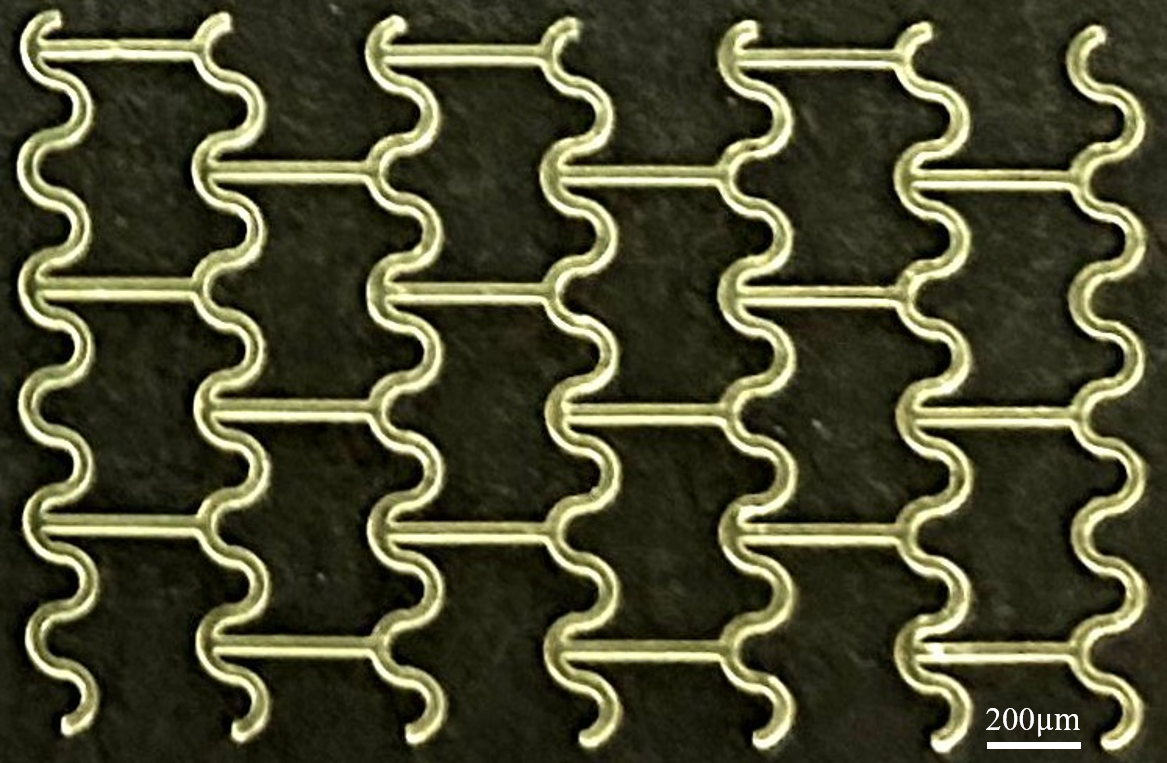

Surface Texturing for Tribological Applications

2020 - 2023 | Completed

Investigation of laser surface texturing techniques to create controlled micro-patterns that reduce friction and wear in mechanical components. The work involves both computational modeling to predict texture features as well as fabrication of texture. The project has demonstrated significant improvements in tribological properties for various applications.

FEM Modeling of Laser Directed Energy Depositon

2019 - 2022 | Completed

The FEM-based thermomechanical model for laser directed energy deposition captures the complex interplay between heat transfer, phase changes, and mechanical stresses to predict residual stresses and metallurgical phase transformations. This approach enables optimization of process parameters for improved build quality and structural integrity. The model serves as a valuable tool for advancing metal additive manufacturing through predictive simulation.

Research Collaborators

Technical University of Denmark

Copenhagen, Denmark

Collaboration on light polymer interaction and volumetric additive manufacturing

KU Leuven

Leuven, Belgium

Joint research on femtosecond laser processing of glass.

Monash University

Monash, Australia

Collaboration on laser DED and laser-based APT.

Central Manufacturing Technology Institute

Bengaluru, India

Industry partnership in the area of femtosecond laser processing.

Defense Materials Research Laboratory

Hyderabad, India

Collaborative research on micromachining of ceramics and superalloys.

Advanced Research Center International

Hyderabad, India

Joint research on femtosecond laser processing.

Interested in Collaboration?

We are always looking for new research collaborators from academia and industry. If you're interested in working with us, please get in touch to discuss potential collaboration opportunities.

Contact Us